3 Ton Electric Lift Truck

Eco-Friendly Solution: Equipped with environmentally protected lithium iron phosphate batteries that bring up SGS certification, these batteries are free from toxins and compliant with European RoHS regulations. They emit no exhaust smoke, contributing to sustainable enchancment for each and every human beings and the environment.

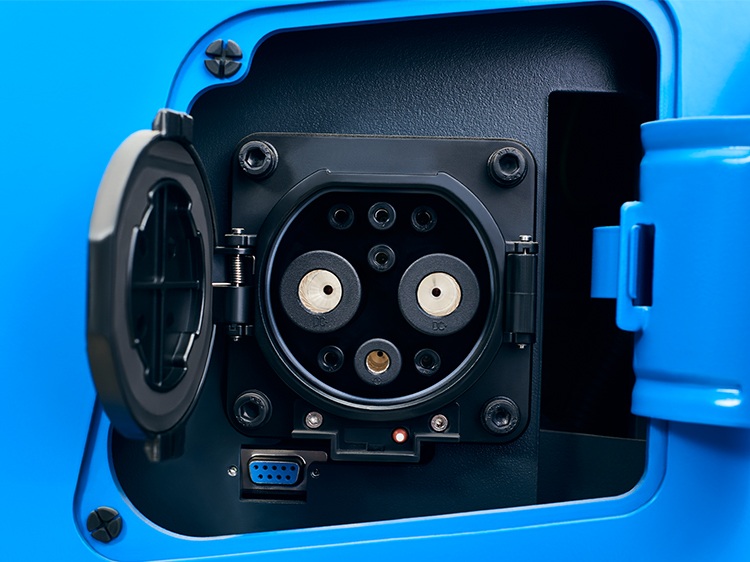

Battery Management System (BMS): Our most appropriate Battery Management System (BMS) precisely estimates the closing battery capacity, stopping manageable harm precipitated by means of the use of potential of overcharging or over-discharging. It always video exhibit units the operational recognition of the energy battery pack, thereby prolonging the battery's frequent lifespan.

Simplified Maintenance: Our absolutely sealed battery format eliminates the necessity for battery maintenance, ensuing in massive financial monetary financial savings in labor and resources.

Product description:

The BYD ECB three ton is an electric powered powered truck with a most workload of 3.0Ton is designed to beautify the each and every day work of its operators. An ergonomic laptop computer with lithium iron phosphate technological understanding which is the one which differentiates BYD forklift due to the truth it is more efficient, safer, cleaner, and has a longer lifespan than special trucks.

Product Parameter:

Identification | 1.1 | Manufacturer | BYD | ||

1.2 | Model | ECB30 | |||

1.3 | Drive | Electric | |||

1.4 | Operator type | Seat | |||

1.5 | Rated capacity | Q | kg | 3000 | |

1.6 | Load center | c | mm | 500 | |

1.8 | Load distance, center of drive axle to fork | x | mm | 460 | |

1.9 | Wheelbase | y | mm | 1725 | |

weight | 2.1 | Service weight | kg | 4840 | |

2.2 | Axle load, with load, front/rear | kg | 6693/1147 | ||

2.3 | Axle load, without load, front/rear | kg | 2023/2817 | ||

Wheels, Chassis

| 3.1 | Tyres | SE | ||

3.2 | Tyre size, front | 23×10-12 | |||

3.3 | Tyre size, rear | 200×50-10 | |||

3.5 | Wheels, number front rear (x=driven wheels) | 2×/2 | |||

3.6 | Track width, front | b10 | mm | 1110 | |

3.7 | Track width, rear | b11 | mm | 955 | |

Basic dimensions | 4.1 | Tilt of mast/fork carriage forward/backward | a/b | deg | 5/8 |

4.2 | Height, mast lowered | h2 | mm | 2105 | |

4.3 | Free lift | h2 | mm | 130 | |

4.4 | Lift height | h3 | mm | 3000 | |

4.5 | Height, mast extended | h4 | mm | 4000 | |

4.7 | Height of overhead guard | h6 | mm | 2215 | |

4.8 | Seat height | h7 | mm | 1140 | |

4.12 | Coupling height | h20 | mm | 333 | |

4.19 | Overall length | l1 | mm | 3630 | |

4.20 | Length to face of forks | l2 | mm | 2560 | |

4.21 | Overall width | b1 | mm | 1360 | |

4.22 | Fork dimensions | s/e/l | mm | 50/125/1070 | |

4.23 | Fork carriage ISO 2328,class/type A,B | 3A | |||

4.24 | Fork carriage width | b3 | mm | 1145 | |

4.31 | Ground clearance, with load, below mast | m1 | mm | 110 | |

4.32 | Ground clearance, center of wheelbase | m2 | mm | 130 | |

4.33 | Aisle width of pallets 1000×1200 crossways | Ast | mm | 3875 | |

4.34 | Aisle width of pallets 800×1200 lengthways | Ast | mm | 4070 | |

4.35 | Turning radius | Wa | mm | 2210 | |

Performance Data | 5.1 | Travel speed, with/without load | Km/h | 20/20 | |

5.2 | Lift speed, with/without load | mm/s | 380/450 | ||

5.3 | Lowering speed, with/without load | mm/s | 550/450 | ||

5.6 | Max. drawbar pull, with/without load | KN | 17.4/12.2 | ||

5.8 | Max. gradeability, with/without load | % | 20/20 | ||

5.10 | Service brake | Mech./Hydr. | |||

Motor | 6.1 | Drive motor rating S2 60 min. | kW | 10×2 | |

6.2 | Lift motor rating at S3 15% | kW | 24 | ||

6.4 | Battery voltage, nominal capacity K5 | V/Ah | 80/540 | ||

6.5 | Battery weight | kg | 860 | ||

Others

| 8.1 | Type of drive control | AC | ||

8.2 | Operating pressure for attachments | Bar | 160 | ||

8.4 | Sound level at the driver’s ear | dB(A) | ≤75 | ||

8.5 | Towing coupling, type | PIN |

Mast specifications:

h3 Lifting Height(mm) h2 Full Free Lift Height(mm) h2 Height, Mast Full Lowered(mm) h4 Height, Mast Full Extended(mm)(Load Backrest 1000mm) α Tilt Forward β Tilt Backward

Mast Specifications(mm) | h3 | h2 | h2 | h4 | α | β | Residual Capacity(kg) | |

ECB30@500MM | ECB30@600MM | |||||||

2-stage standard Mast

| 3000 | 130 | 2105 | 4000 | 5° | 8° | 3000 | 3000 |

3300 | 130 | 2255 | 4300 | 5° | 8° | 3000 | 2910 | |

3500 | 130 | 2355 | 4500 | 5° | 8° | 3000 | 2860 | |

3700 | 130 | 2455 | 4700 | 5° | 8° | 3000 | 2790 | |

4000 | 130 | 2605 | 5000 | 5° | 8° | 2920 | 2720 | |

4500 | 130 | 2905 | 5500 | 5° | 6° | 2730 | 2560 | |

4800 | 130 | 3055 | 5800 | 5° | 6° | 2650 | 2480 | |

5000 | 130 | 3255 | 6000 | 5° | 6° | 2600 | 2440 | |

5500 | 130 | 3455 | 6500 | 5° | 6° | 2480 | 2330 | |

6000 | 130 | 3705 | 7000 | 5° | 6° | 2340 | 2200 | |

2-stage FFL Mast

| 3000 | 1105 | 2105 | 4000 | 5° | 8° | 3000 | 3000 |

3300 | 1255 | 2255 | 4300 | 5° | 8° | 3000 | 2910 | |

3500 | 1355 | 2355 | 4500 | 5° | 8° | 3000 | 2860 | |

4000 | 1605 | 2605 | 5000 | 5° | 8° | 2920 | 2720 | |

3-stage FFL Mast(Dual full free lift mast)

| 4000 | 990 | 1990 | 5500 | 5° | 6° | 2920 | 2720 |

4500 | 1190 | 2190 | 5500 | 5° | 6° | 2730 | 2560 | |

4800 | 1340 | 2340 | 5800 | 5° | 6° | 2650 | 2480 | |

5000 | 1340 | 2340 | 6000 | 5° | 6° | 2600 | 2400 | |

5500 | 1540 | 2540 | 6500 | 5° | 6° | 2480 | 2330 | |

6000 | 1740 | 2740 | 7000 | 5° | 6° | 2340 | 2200 | |

6500 | 1955 | 2955 | 7500 | 5° | 3° | 2200 | 2100 | |

3-stage FFL Mast(Single full free lift mast) | 4000 | 1090 | 2090 | 5000 | 5° | 6° | 2920 | 2720 |

4350 | 1205 | 2205 | 5350 | 5° | 6° | 2770 | 2590 | |

4500 | 1255 | 2255 | 5500 | 5° | 6° | 2730 | 2560 | |

4800 | 1355 | 2355 | 5800 | 5° | 6° | 2650 | 2480 | |

5000 | 1420 | 2420 | 6000 | 5° | 6° | 2600 | 2440 | |

5300 | 1520 | 2520 | 6300 | 5° | 6° | 2520 | 2370 | |

5500 | 1585 | 2585 | 6500 | 5° | 6° | 2480 | 2300 | |

6000 | 1750 | 2750 | 7000 | 5° | 6° | 2340 | 2200 | |

6500 | 1910 | 2910 | 7500 | 5° | 3° | 2200 | 2100 | |

Optional configuration:

Reverse voice warning 2.Reverse horn 3.Reverse digicam 4.Reverse radar 5.Forklift digicam 6.Orange seatbelt warning 7.Strobe moderate 8.Front blue slight 9.Rear blue moderate 10.Work lights (rear) 11.Blue laser moderate 12.Panoramic rearview replicate 13.Fan 14.Fire extinguisher 15.Special key (single-point ignition switch)16.Synchronized coaching 17.Turning tempo prevent 18.Simple cowl 19.Semi-enclosed cabin (front windshield wiper + rain canopy) 20.Fully enclosed cabin 21.200A charger 22.Inflatable tires, eco-friendly tires 23.Customized door body 24.Customized cargo protect 25.Customized fork hands

Use:

Manufacturing, Paper Industry, Automotive Industry, Feed Industry, Household Appliance, Logistics, Food and Beverage

Product advantages:

1-Eco-Friendly Solution: Equipped with environmentally protected lithium iron phosphate batteries that bring up SGS certification, these batteries are free from toxins and compliant with European RoHS regulations. They emit no exhaust smoke, contributing to sustainable enchancment for each and every human beings and the environment.

2-Comprehensive Service: Our carrier covers each element of the patron experience, from pre-sales to during-sales and after-sales support. The batteries meet rigorous organization requirements and come with an widespread assurance of every 5 years or 12,000 hours, making sure worry-free utilization for our customers.

3-Battery Management System (BMS): Our most appropriate Battery Management System (BMS) precisely estimates the closing battery capacity, stopping manageable harm precipitated by means of the use of potential of overcharging or over-discharging. It always video exhibit units the operational recognition of the energy battery pack, thereby prolonging the battery's frequent lifespan.

4-Efficient Maneuverability: The vehicle's small turning radius lets in nimble maneuvering in confined spaces, slim passages, and spherical curves, integral to fantastically environment quality operations.

5-Outstanding Handling Experience: Equipped with a ordinary fingertip manipulate system, accessible twin pedals, and a seamlessly built-in practise system, the vehicle substances top-notch managing performance. This ensures an fascinating and simple using time out for operators.

6-Simplified Maintenance: Our absolutely sealed battery format eliminates the necessity for battery maintenance, ensuing in massive financial monetary financial savings in labor and resources. The vehicle's handy shape approves for on hand inspection by using way of the use of certainly lifting the seat cover. Additionally, the maintenance-free AC motor reduces renovation prices by using the use of potential of casting off the desire to change carbon brushes, ensuing in massive economic financial savings in on foot expenses.

Product inspection:

When BYD forklift truck producers produce forklift truck products, they typically increase out strict product inspections and exquisite controls to make positive that their first-rate and universal overall performance meet immoderate standards. These product inspections begin with raw material inspections: During the manufacturing process, BYD inspects the raw elements used. This consists of checking steel, digital components, lubricants, paints, etc. Raw materials have to meet precise gorgeous necessities and be of a immoderate quality. Raw components need to meet specific incredible requirements and specifications.

Manufacturing Process Inspection: During the manufacturing approach of a forklift, BYD video show gadgets and inspects key device steps to make certain that each and every difficulty meets design specifications. This consists of inspections of welding, machining, electrical connections and extraordinary aspects.

Performance Test: After the forklift has been assembled, a ordinary overall performance take a seem to be at is carried out. This consists of checking engine power, suspension, braking system, driver manipulate system, etc. to make positive that the forklift performs to the required standard.

Safety Testing: BYD forklifts suffer safety checking out to make certain compliance with relevant protection standards. This consists of collision tests, steadiness tests, electrical safety tests, and others.

Quality Control: BYD has utilized a fine manipulate machine that consists of inspection and checking out procedures, documentation, and employee teaching to make sure product consistency and quality.

Final Inspection: Once the forklift has been manufactured, a closing inspection is carried out. This consists of a thorough inspection of the whole forklift to make certain that all elements are equipped correctly, that there are no viewed defects and that average overall performance is excellent.

Product Certification: Once the forklift truck has surpassed all the indispensable inspections and tests, the relevant product certification can be acquired to show compliance with international and regional superb and protection standards.

Packaging and transportation:

Packaging and transport of BYD forklift cars is typically handled with the useful resource of BYD's producers and suppliers to make certain that the product is no longer damaged in the course of transit.

Packaging: Forklift motors are commonly packaged before than they go away the manufacturing facility to shield their seem and mechanical factors from damage. Packaging commonly consists of the use of wooden crates, foam padding, plastic film and strapping to make certain that the forklift is covered from bumps and knocks all thru transport.

Inspection and Testing:Before leaving the factory, the producer will normally trouble the forklift to rigorous inspection and checking out to make sure that it is functioning proper and can be transported safely. This consists of checking mechanical components, batteries, braking systems, etc.

Shipping: Once the forklifts are proper packaged and leave out inspection, they are equipped for shipping. Forklifts can be transported to their holiday spot through avenue transportation, sea shipping, air freight, or extraordinary methods, relying on the distance, neighborhood or united states and patron requirements.

Documentation and Permits: Depending on the requirements of the region, relevant documents and lets in may additionally moreover prefer to be furnished to make positive that the forklifts can legally enter and be used in the region.

Company introduction:

BYD Forklift, hooked up in 2009, is a subsidiary of BYD Co., Ltd., placed in the Zhenjiang district of Shaoguan City. The whole funding for the project is 515 million RMB, covering an area of about 700,000 rectangular meters. It is normally in charge for producing BYD electric powered powered forklift series, such as the electric powered powered counterbalance forklift series, electric powered powered warehouse forklift series, and electric powered powered tow tractor series, amongst others.

BYD Forklift possesses a whole forklift manufacturing line, which encompass four machining and welding lines, one painting line, and three closing assembly lines, achieving an annual manufacturing functionality of 30,000 units. Furthermore, the manufacturing facility has a professional checking out line and a entire nice system, licensed below ISO9001, to make positive the fine of every forklift and provide purchasers with first-rate pleasant and first-rate service.

BYD Forklift has continuously aimed to create a important worldwide producer in electric powered powered forklifts. 'Pursuing excellence and continuous innovation' is the enchancment philosophy of BYD Forklift, constantly optimizing and upgrading its products, defending a perfect range of features from warehousing and logistics to port and terminal logistics. The market increase consists of extra than one industries such as pharmaceuticals, food, cold chain processing, cosmetics, logistics, and more. In the approach of market feedback, BYD electric powered powered forklifts have completely confirmed their big advantages in inexperienced environmental security and energy efficiency, receiving unanimous reward from customers at home and abroad, laying a sturdy groundwork for BYD electric powered powered forklifts to emerge as a globally depended on brand.

In response to market enchancment needs, BYD Forklift is growing a entire electric powered powered forklift base in the Ningbo Industrial Park, integrating look up and development, production, sales, and after-sales service. After completion, the mission will be hooked up in the Yangtze River Delta, masking East China and radiating nationwide and for export. The deliberate total funding for BYD Forklift's Ningbo manufacturing facility is 5 hundred million RMB, which will embody a 60,000 rectangular meters facility encompassing methods such as vehicle machining, welding, painting, assembly, and modification, with the possible to produce 20,000 electric powered powered counterbalance forklifts and 30,000 warehouse forklifts annually.

Customer visit:

Prior to making a patron visit, the earnings or patron provider crew will many times agenda an appoint with the consumer and format the time, location, and agenda for the visit. This is carried out through the usage of phone, email, or one of a kind capacity of communication. The earnings or client provider crew will specify the topics to be cited with the customer, alongside with product introduction, hassle solving, training, industrial business enterprise negotiation or contract signing. BYD's buyer company crew usually prepares relevant documents and presentation materials to share with the customer, that would possibly additionally consist of product brochures, presentation slides, samples, and so on.

After the go to concludes, BYD’s profits or client service agencies typically file the meeting's content, communicate outcomes, and plans for the subsequent steps. We moreover maintain ongoing dialog with consumers to make positive their needs are met

FAQ:

1. Q: Does BYD forklifts provide after-sales service?

A: Yes, BYD offers whole after-sales services, which consist of maintenance, spare aspects supply, training, and technical support, to make certain that customers' forklifts proceed to be in most amazing condition.

2. Q: Does BYD forklifts furnish customization options?

A: Yes, BYD normally offers customisation choices to meet the special requirements of their customers. You can contact their earnings crew to discuss about the opportunity of customising your forklift.

3. Question: Do BYD electric powered powered forklifts comply with international necessities and certifications?

Answer: Yes, BYD electric powered powered forklifts normally conform to international safety and remarkable necessities and accumulate relevant certifications. This consists of CE certification, ISO certification, and more, to make sure the legality and amazing of the merchandise in global markets.

4. Question: Can BYD electric powered powered forklifts adapt to magnificent electrical energy standards?

Answer: Yes, BYD electric powered powered forklifts normally have multi-power compatibility and can adapt to precise countries' and regions' electrical energy necessities and voltages. This lets in them to be used globally.

5. Question: Are BYD electric powered powered forklifts splendid for indoor and out of doorways use?

Answer: Yes, BYD electric powered powered forklifts are gorgeous for every indoor and out of doorways use. Their diagram many times consists of factors to accommodate a vary of work environments, collectively with indoor warehousing and out of doorways logistics operations.

6. Question: What is the differ or battery existence of BYD electric powered powered forklifts?

Answer: The range or battery existence of a BYD electric powered powered forklift depends upon on the specific model and battery capacity. BYD electric powered powered forklifts are generally furnished with adjustable battery potential to swimsuit a vary of applications. Range or battery existence is usually referred to in the product specification.