Wholesale Distribution Forklift Truck 3.0T

1. Extended Warranty We put in force excessive enterprise requirements for warranties: 5 years or 12,000 hours for the battery, virtually making sure client peace of mind.

2. High Safety The car is outfitted with features such as slope-holding protection, overload protection, high-level tilt protection, automobile power-off protection, turning velocity limit, and mast low-level buffering, making sure that the forklift is continually in a secure working condition. Reverse warning lights, and reverse voice reminders beautify personnel safety.

3. Stringent Selection Strict element selection, matching, and checking out to make certain that factors are professional, reliable, and durable. The whole automobile undergoes reliability, stability, safety, and remedy tests, making sure that every automobile reaches its most appropriate running condition.

Product description:

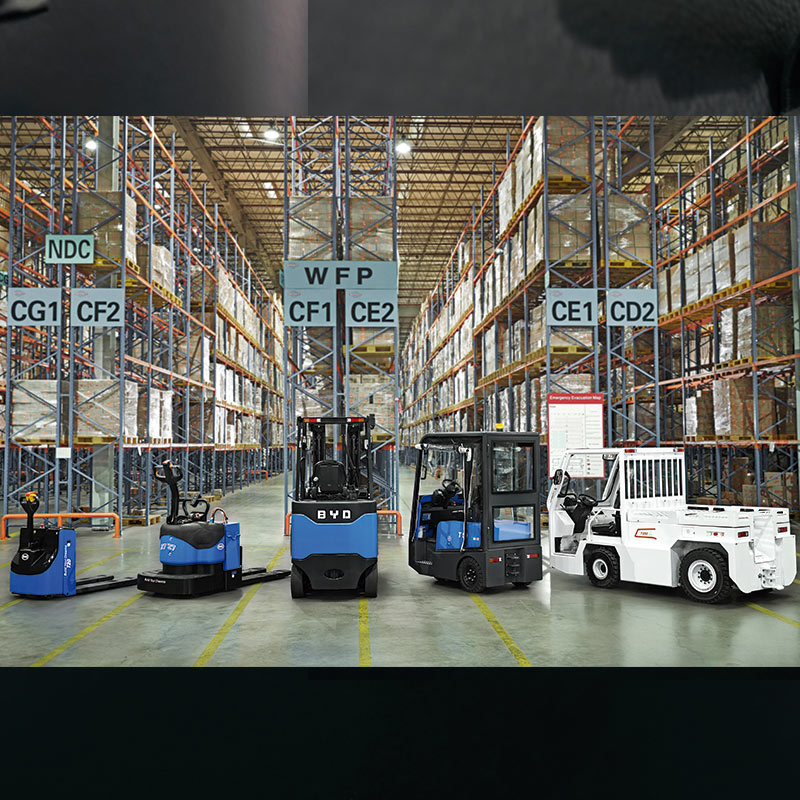

The BYD ECB30 is an electric powered truck with a most workload of 3.0Ton, designed to enhance the every day work of its operators. An ergonomic computing device with lithium iron phosphate technological know-how which is the one which differentiates BYD Forklift due to the fact it is extra efficient, safer, cleaner, and has a longer lifespan than different trucks.

Product Parameter:

Identification | 1.1 | Manufacturer | BYD | ||

1.2 | Model | ECB30 | |||

1.3 | Drive | Electric | |||

1.4 | Operator type | Seat | |||

1.5 | Rated capacity | Q | kg | 3000 | |

1.6 | Load center | c | mm | 500 | |

1.8 | Load distance, center of drive axle to fork | x | mm | 460 | |

1.9 | Wheelbase | y | mm | 1725 | |

weight | 2.1 | Service weight | kg | 4840 | |

2.2 | Axle load, with load, front/rear | kg | 6693/1147 | ||

2.3 | Axle load, without load, front/rear | kg | 2023/2817 | ||

Wheels, Chassis

| 3.1 | Tyres | SE | ||

3.2 | Tyre size, front | 23×10-12 | |||

3.3 | Tyre size, rear | 200×50-10 | |||

3.5 | Wheels, number front rear (x=driven wheels) | 2×/2 | |||

3.6 | Track width, front | b10 | mm | 1110 | |

3.7 | Track width, rear | b11 | mm | 955 | |

Basic dimensions | 4.1 | Tilt of mast/fork carriage forward/backward | a/b | deg | 5/8 |

4.2 | Height, mast lowered | h2 | mm | 2105 | |

4.3 | Free lift | h2 | mm | 130 | |

4.4 | Lift height | h3 | mm | 3000 | |

4.5 | Height, mast extended | h4 | mm | 4000 | |

4.7 | Height of overhead guard | h6 | mm | 2215 | |

4.8 | Seat height | h7 | mm | 1140 | |

4.12 | Coupling height | h20 | mm | 333 | |

4.19 | Overall length | l1 | mm | 3630 | |

4.20 | Length to face of forks | l2 | mm | 2560 | |

4.21 | Overall width | b1 | mm | 1360 | |

4.22 | Fork dimensions | s/e/l | mm | 50/125/1070 | |

4.23 | Fork carriage ISO 2328,class/type A,B | 3A | |||

4.24 | Fork carriage width | b3 | mm | 1145 | |

4.31 | Ground clearance, with load, below mast | m1 | mm | 110 | |

4.32 | Ground clearance, center of wheelbase | m2 | mm | 130 | |

4.33 | Aisle width of pallets 1000×1200 crossways | Ast | mm | 3875 | |

4.34 | Aisle width of pallets 800×1200 lengthways | Ast | mm | 4070 | |

4.35 | Turning radius | Wa | mm | 2210 | |

Performance Data | 5.1 | Travel speed, with/without load | Km/h | 20/20 | |

5.2 | Lift speed, with/without load | mm/s | 380/450 | ||

5.3 | Lowering speed, with/without load | mm/s | 550/450 | ||

5.6 | Max. drawbar pull, with/without load | KN | 17.4/12.2 | ||

5.8 | Max. gradeability, with/without load | % | 20/20 | ||

5.10 | Service brake | Mech./Hydr. | |||

Motor | 6.1 | Drive motor rating S2 60 min. | kW | 10×2 | |

6.2 | Lift motor rating at S3 15% | kW | 24 | ||

6.4 | Battery voltage, nominal capacity K5 | V/Ah | 80/540 | ||

6.5 | Battery weight | kg | 860 | ||

Others

| 8.1 | Type of drive control | AC | ||

8.2 | Operating pressure for attachments | Bar | 160 | ||

8.4 | Sound level at the driver’s ear | dB(A) | ≤75 | ||

8.5 | Towing coupling, type | PIN |

Mast specifications

h3 Lifting Height(mm) h2 Full Free Lift Height(mm) h2 Height, Mast Full Lowered(mm) h4 Height, Mast Full Extended(mm)(Load Backrest 1000mm) α Tilt Forward β Tilt Backward

Mast Specifications(mm) | h3 | h2 | h2 | h4 | α | β | Residual Capacity(kg) | |

ECB30@500MM | ECB30@600MM | |||||||

2-stage standard Mast

| 3000 | 130 | 2105 | 4000 | 5° | 8° | 3000 | 3000 |

3300 | 130 | 2255 | 4300 | 5° | 8° | 3000 | 2910 | |

3500 | 130 | 2355 | 4500 | 5° | 8° | 3000 | 2860 | |

3700 | 130 | 2455 | 4700 | 5° | 8° | 3000 | 2790 | |

4000 | 130 | 2605 | 5000 | 5° | 8° | 2920 | 2720 | |

4500 | 130 | 2905 | 5500 | 5° | 6° | 2730 | 2560 | |

4800 | 130 | 3055 | 5800 | 5° | 6° | 2650 | 2480 | |

5000 | 130 | 3255 | 6000 | 5° | 6° | 2600 | 2440 | |

5500 | 130 | 3455 | 6500 | 5° | 6° | 2480 | 2330 | |

6000 | 130 | 3705 | 7000 | 5° | 6° | 2340 | 2200 | |

2-stage FFL Mast

| 3000 | 1105 | 2105 | 4000 | 5° | 8° | 3000 | 3000 |

3300 | 1255 | 2255 | 4300 | 5° | 8° | 3000 | 2910 | |

3500 | 1355 | 2355 | 4500 | 5° | 8° | 3000 | 2860 | |

4000 | 1605 | 2605 | 5000 | 5° | 8° | 2920 | 2720 | |

3-stage FFL Mast(Dual full free lift mast)

| 4000 | 990 | 1990 | 5500 | 5° | 6° | 2920 | 2720 |

4500 | 1190 | 2190 | 5500 | 5° | 6° | 2730 | 2560 | |

4800 | 1340 | 2340 | 5800 | 5° | 6° | 2650 | 2480 | |

5000 | 1340 | 2340 | 6000 | 5° | 6° | 2600 | 2400 | |

5500 | 1540 | 2540 | 6500 | 5° | 6° | 2480 | 2330 | |

6000 | 1740 | 2740 | 7000 | 5° | 6° | 2340 | 2200 | |

6500 | 1955 | 2955 | 7500 | 5° | 3° | 2200 | 2100 | |

3-stage FFL Mast(Single full free lift mast) | 4000 | 1090 | 2090 | 5000 | 5° | 6° | 2920 | 2720 |

4350 | 1205 | 2205 | 5350 | 5° | 6° | 2770 | 2590 | |

4500 | 1255 | 2255 | 5500 | 5° | 6° | 2730 | 2560 | |

4800 | 1355 | 2355 | 5800 | 5° | 6° | 2650 | 2480 | |

5000 | 1420 | 2420 | 6000 | 5° | 6° | 2600 | 2440 | |

5300 | 1520 | 2520 | 6300 | 5° | 6° | 2520 | 2370 | |

5500 | 1585 | 2585 | 6500 | 5° | 6° | 2480 | 2300 | |

6000 | 1750 | 2750 | 7000 | 5° | 6° | 2340 | 2200 | |

6500 | 1910 | 2910 | 7500 | 5° | 3° | 2200 | 2100 | |

Classification:

1.Multi-function armrest with fingertip control

2.Seat with full suspension

3.Mast with full free double lifting cylinders

4.Curve velocity adjustment to enhance balance and minimize chance of overturning

5.Brake help when it detects that the operator is releasing the brake on a ramp or slope

6.Limitation of the the front tilt attitude to limit the danger of load drop

7.When the load exceeds 10% of the set weight, the engine stops working for safety's sake

8.Multifunction TFT show with scrolling speed, ultimate battery capacity, clock with working hours and gathered hours, and three pace modes

Optional configuration:

1.Reverse voice warning 2.Reverse horn 3.Reverse digital camera 4.Reverse radar 5.Forklift digital camera 6.Orange seatbelt warning 7.Strobe slight 8.Front blue moderate 9.Rear blue moderate 10.Work lighting fixtures (rear) 11.Blue laser moderate 12.Panoramic rearview replicate 13.Fan 14.Fire extinguisher 15.Special key (single-point ignition switch) 16.Synchronized education 17.Turning pace preclude 18.Simple cowl 19.Semi-enclosed cabin (front windshield wiper + rain canopy) 20.Fully enclosed cabin 21.200A charger 22.Inflatable tires, eco-friendly tires 23.Customized door physique 24.Customized cargo guard 25.Customized fork arms

Use:

Manufacturing, Paper Industry, Automotive Industry, Feed Industry, Household Appliance, Logistics, Food and Beverage

Product advantages:

1.Extended Warranty : We keep our assurance to a immoderate organization standard: a 5-year or 12,000-hour battery assurance offers real peace of notion for our customers.

2.High safety : The vehicle is equipped with slope keeping protection, overload protection, immoderate tilt protection, vehicle energy failure protection, turning pace hinder and low gantry buffer to make certain that the forklift is consistently in a impenetrable working condition. Reversing warning moderate and reversing voice reminder attribute can embellish personnel safety.

3.Strict Selection Rigorous element selection, matching and checking out ensures professionalism, reliability and sturdiness of components. The entire automobile is examined for reliability, stability, protection and alleviation to make positive that each vehicle operates at its best.

4.Ergonomic mechanical suspension seat with OPS characteristic for safety and comfort. Spacious supportive workspace, clear and open pinnacle and the the front visibility, large reversing assist take care of for on hand and blissful operation, multifunctional coloration exhibit for handy get proper of entry to to car information.

5.Easy protection The auto form is effortless and the seat can be lifted for reachable maintenance. The AC motor requires no safety and the battery is maintenance-free, decreasing the cost of altering carbon brushes and along with distilled water, substantially decreasing strolling costs.

Product inspection:

When BYD forklift truck producers manufacture forklift truck products, they typically raise out strict product inspections and exceptional controls to make certain that their fantastic and overall performance meet excessive standards. These product inspections start with uncooked cloth inspections: During the manufacturing process, BYD inspects the uncooked substances used. This consists of checking steel, digital components, lubricants, paints, etc. Raw substances ought to meet particular fantastic requirements and be of a excessive quality. Raw substances have to meet precise exceptional requirements and specifications.

Manufacturing Process Inspection: During the manufacturing manner of a forklift, BYD video display units and inspects key technique steps to make certain that every element meets graph specifications. This consists of inspections of welding, machining, electrical connections and different aspects.

Performance Test: After the forklift has been assembled, a overall performance check is carried out. This consists of checking engine power, suspension, braking system, driver manipulate system, etc. to make sure that the forklift performs to the required standard.

Safety Testing: BYD forklifts endure security checking out to make sure compliance with applicable security standards. This consists of collision tests, steadiness tests, electrical protection tests, and others.

Quality Control: BYD has applied a first-class manage machine that consists of inspection and checking out procedures, documentation, and worker coaching to make certain product consistency and quality.

Final Inspection: Once the forklift has been manufactured, a closing inspection is carried out. This includes a thorough inspection of the whole forklift to make sure that all factors are outfitted correctly, that there are no seen defects and that overall performance is excellent.

Product Certification: Once the forklift truck has handed all the essential inspections and tests, the applicable product certification can be got to display compliance with worldwide and regional best and security standards.

Packaging and transportation:

Packaging and delivery of BYD forklift vans is typically treated through BYD's producers and suppliers to make certain that the product is no longer broken at some stage in transit.

Packaging: Forklift vans are generally packaged earlier than they depart the manufacturing unit to defend their look and mechanical aspects from damage. Packaging generally consists of the use of wood crates, foam padding, plastic movie and strapping to make sure that the forklift is included from bumps and knocks at some point of transport.

Inspection and Testing: Before leaving the factory, the producer will commonly problem the forklift to rigorous inspection and checking out to make sure that it is functioning accurate and can be transported safely. This consists of checking mechanical components, batteries, braking systems, etc.

Shipping: Once the forklifts are right packaged and skip inspection, they are organized for shipping. Forklifts can be transported to their destination, sea shipping, air freight, or different methods, relying on the distance, vicinity and consumer requirements.

Documentation and Permits: Depending on the necessities of the destination or region, applicable files and allows may additionally want to be furnished to make certain that the forklifts can legally enter and be used in the destination or region.

Company introduction:

BYD Forklift, installed in 2009, is a subsidiary of BYD Co., Ltd., placed in the Zhenjiang district of Shaoguan City. The whole funding for the challenge is 515 million RMB, protecting a location of about 700,000 rectangular meters. It is in general accountable for producing BYD electric powered forklift series, which include the electric powered counterbalance forklift series, electric powered warehouse forklift series, and electric powered tow tractor series, amongst others.

BYD Forklift possesses a whole forklift manufacturing line, together with 4 machining and welding lines, one portray line, and three ultimate meeting lines, reaching an annual manufacturing ability of 30,000 units. Furthermore, the manufacturing unit has a expert checking out line and a complete exceptional system, licensed underneath ISO9001, to make certain the high-quality of each forklift and supply clients with great excellent and notable service.

BYD Forklift has constantly aimed to create a main international manufacturer in electric powered forklifts. 'Pursuing excellence and non-stop innovation' is the improvement philosophy of BYD Forklift, always optimizing and upgrading its products, protecting a ideal vary of functions from warehousing and logistics to port and terminal logistics. The market enlargement consists of more than one industries such as pharmaceuticals, food, bloodless chain processing, cosmetics, logistics, and more. In the technique of market feedback, BYD electric powered forklifts have entirely confirmed their tremendous blessings in inexperienced environmental safety and strength efficiency, receiving unanimous reward from clients at domestic and abroad, laying a stable basis for BYD electric powered forklifts to turn out to be a globally depended on brand.

In response to market improvement needs, BYD Forklift is establishing a complete electric powered forklift base in the Ningbo Industrial Park, integrating lookup and development, production, sales, and after-sales service. After completion, the challenge will be situated in the Yangtze River Delta, overlaying East China and radiating nationwide and for export. The deliberate complete funding for BYD Forklift's Ningbo manufacturing facility is five hundred million RMB, which will encompass a 60,000 rectangular meters facility encompassing tactics such as car machining, welding, painting, assembly, and modification, with the capability to produce 20,000 electric powered counterbalance forklifts and 30,000 warehouse forklifts annually.

Customer visit:

Prior to making a purchaser visit, the earnings or patron issuer crew will commonly agenda an appoint with the purchaser and sketch the time, location, and agenda for the visit. This is done via phone, email, or distinct capability of communication. The earnings or customer provider crew will specify the things to be noted with the customer, which consist of product introduction, hassle solving, training, agency negotiation or contract signing. BYD's purchaser issuer crew commonly prepares relevant documents and presentation supplies to share with the customer, that may additionally additionally consist of product brochures, presentation slides, samples, and so on.

After the go to concludes, BYD’s earnings or client company corporations generally document the meeting's content, communicate outcomes, and plans for the subsequent steps. We moreover maintain ongoing verbal alternate with purchasers to make positive their needs are met

FAQ:

1. Q: Does BYD forklifts furnish after-sales service?

A: Yes, BYD presents complete after-sales services, together with maintenance, spare components supply, training, and technical support, to make certain that customers' forklifts continue to be in most beneficial condition.

2. Q: Does BYD forklifts provide customization options?

A: Yes, BYD generally presents customisation preferences to meet the precise necessities of their customers. You can contact their income crew to talk about the opportunity of customising your forklift.

3. Question: Do BYD electric powered forklifts comply with global requirements and certifications?

Answer: Yes, BYD electric powered forklifts usually conform to global protection and excellent requirements and achieve applicable certifications. This consists of CE certification, ISO certification, and more, to make certain the legality and satisfactory of the merchandise in global markets.

4. Question: Can BYD electric powered forklifts adapt to specific electricity standards?

Answer: Yes, BYD electric powered forklifts commonly have multi-power compatibility and can adapt to specific countries' and regions' strength requirements and voltages. This approves them to be used globally.

5. Question: Are BYD electric powered forklifts appropriate for indoor and out of doors use?

Answer: Yes, BYD electric powered forklifts are appropriate for each indoor and outside use. Their format generally consists of elements to accommodate a range of work environments, along with indoor warehousing and outside logistics operations.

6. Question: What is the vary or battery existence of BYD electric powered forklifts?

Answer: The vary or battery lifestyles of a BYD electric powered forklift relies upon on the unique mannequin and battery capacity. BYD electric powered forklifts are commonly provided with adjustable battery ability to go well with a range of applications. Range or battery existence is normally mentioned in the product specification.