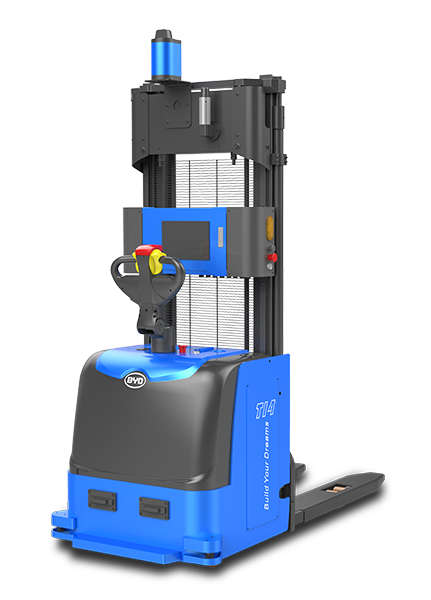

Automated Stacker AS14MPW

High Precision: Laser radar is used to realize the scene and obstacles, growing real-time maps and correcting the robot's position, correctly planning trajectories to keep away from obstacles.

High Safety: Non-contact protection sketch makes use of laser scanners, ultrasonic sensors, etc., in my opinion or in combination, to perceive surrounding boundaries and notice them from a lengthy distance. Safety control, velocity monitoring, emergency stop, and a number techniques are employed for one of a kind conditions, bettering protection performance. Audible and visible alarms, warning horns, and warning lights notably enhance the robot's operational safety, Mechnical bumper collision prevention, when the robotic comes into contact with an obstacle, it stops automatically.

Remote Operation: Remote manipulate of the car can be done the usage of a far off controller, enabling one-to-many operations (one far off manage related to more than one vehicles).

Dispatch System: Equipped with a car dispatch system, it video display units and manages all AGV subject operations, offering real-time remarks on car popularity information. Task scheduling, assignment analysis, and practical venture project primarily based on assignment priorities. System integration: open machine integration competencies supplying personalized interface services.

Product Description:

The BYD AS14MPW is an automatic navigation transport robotic designed for carrying out cloth dealing with duties in locations such as factories, warehouses, and logistics centers. It is succesful of independent navigation and executing duties routinely barring the want for guide operation, appreciably bettering operational efficiency. This forklift elements a balanced weight design, offering amazing steadiness and load-carrying capacity. It can safely and reliably transport heavy goods, making sure a excessive degree of operational stability.

Product Parameter

Identification | 1.1 | Manufacturer | BYD | ||

1.2 | Model | AS14MPW | |||

1.3 | Drive | Electric | |||

1.4 | Operator type | Autonomous Driving | |||

1.5 | Load capacity | kg | 1400 | ||

Weight | 2.1 | Service weight (including battery) | kg | 880 | |

Dimension | 4.19 | Overall length | l1 | mm | 1980 |

4.21 | Overall width | b1 | mm | 895 | |

4.22 | Fork dimensions | mm | 1150/180/61 | ||

4.35 | Minimum Turning radius | Wa | mm | 1564 | |

Performance Data | 5.1 | Travel speed, with/without load | mm/s | 0-1200 | |

5.2 | Lift speed with/without load | mm/s | 0-140 | ||

5.3 | Lowering speed with/without load | mm/s | 0-200 | ||

Lifting height | mm | 3000 | |||

Battery voltage/capacity | V/Ah | 24/130 | |||

Linear Tracking Accuracy | mm | ±10 | |||

Repeat Accuracy to Stations | mm | ±10 |

Optional configuration:

Vehicle Side Laser Collision Sensor

Vehicle Dispatch System

Warehouse Management System

QR Code-Assisted Positioning

Human-Machine Interaction Display Screen

Fork Direction Bottom Laser Collision Sensor

Use:

Warehousing and Logistics industry, manufacturing industry, Commercial and retail industry, food and beverage industry, Medical facilities industry, agriculture, Large scale construction side, Ports and freight terminals.

Product advantages:

High Precision: Laser radar is used to realize the scene and obstacles, developing real-time maps and correcting the robot's position, efficiently planning trajectories to keep away from obstacles.

High Safety: Non-contact security sketch makes use of laser scanners, ultrasonic sensors, etc., in my view or in combination, to become aware of surrounding boundaries and realize them from a lengthy distance. Safety control, pace monitoring, emergency stop, and quite a number strategies are employed for exclusive conditions, bettering protection performance. Audible and visible alarms, warning horns, and warning lights substantially enhance the robot's operational safety, Mechanical bumper collision prevention, when the robotic comes into contact with an obstacle, it stops automatically.

Remote Operation: Remote manipulate of the automobile can be completed the use of a faraway controller, enabling one-to-many operations (one faraway manage linked to a couple of vehicles).

Dispatch System: Equipped with a automobile dispatch system, it video display units and manages all AGV subject operations, imparting real-time remarks on automobile repute information. Task scheduling, undertaking analysis, and realistic project mission primarily based on project priorities. System integration: open gadget integration skills imparting personalized interface services.

Product inspection:

BYD forklift producer generally conducts rigorous product inspections and exceptional manage when producing forklift merchandise to make sure that their fine and overall performance meet excessive standards. These product inspects starts offevolved as from Raw Material Inspection: During the manufacturing process, BYD inspects the uncooked materials used. This consists of checking steel, digital components, lubricants, coatings, and more. Raw substances ought to meet particular excellent requirements and specifications.

Manufacturing Process Inspection: During the forklift's manufacturing process, BYD video display units and inspects key procedure steps to make sure that every thing meets plan specifications. This consists of inspections of welding, mechanical processing, electrical connections, and different aspects.

Performance Testing: After the forklift is assembled, overall performance trying out is conducted. This consists of checking engine power, suspension systems, brake systems, driver manage systems, and extra to make sure that the forklift's overall performance meets specific standards.

Safety Testing: BYD forklifts endure protection checking out to make sure compliance with applicable security standards. This consists of collision tests, balance tests, electrical protection tests, and others.

Quality Control: BYD implements a exceptional manage system, such as inspection and trying out procedures, record records, worker training, and more, to make sure product consistency and quality.

Final Inspection: After the completion of forklift production, a ultimate inspection is performed. This includes a complete take a look at of the whole forklift to make sure that all aspects are set up correctly, there are no apparent defects, and overall performance is excellent.

Product Certification: Once the forklifts omit all quintessential inspections and tests, they may also obtain applicable product certifications to show compliance with worldwide and regional satisfactory and protection standards.

Packaging and transportation:

The packaging and transportation of forklifts are normally treated by way of the producer and suppliers to make sure that the merchandise are now not broken for the duration of transit.

Packaging: Forklifts are commonly packaged earlier than leaving the manufacturing facility to defend their look and mechanical aspects from damage. Packaging usually consists of the use of timber crates, foam padding, plastic film, and strapping substances to make certain that the forklifts are now not affected by using bumps and collisions at some stage in transportation.

Inspection and Testing: Before leaving the factory, producers normally behavior rigorous inspections and trying out on the forklifts to make sure that they characteristic precise and can be safely transported. This consists of checking mechanical components, batteries, brake systems, and more.

Shipping: Once the forklifts are exact packaged and bypass inspection, they are organized for shipping. Forklifts can be transported to their vacation spot by using avenue transportation, sea shipping, air freight, or different methods, relying on the distance, location and purchaser requirements.

Documentation and Permits: Depending on the necessities of the destination or region, applicable files and lets in can also want to be supplied to make sure that the forklifts can legally enter and be used in the Destination or region.

Company introduction:

BYD Forklift, installed in 2009, is a subsidiary of BYD Co., Ltd., placed in the Zhenjiang district of Shaoguan City. The whole funding for the challenge is 515 million RMB, protecting an place of about 700,000 rectangular meters. It is by and large accountable for producing BYD electric powered forklift series, which includes the electric powered counterbalance forklift series, electric powered warehouse forklift series, and electric powered tow tractor series, amongst others.

BYD Forklift possesses a entire forklift manufacturing line, along with 4 machining and welding lines, one portray line, and three last meeting lines, attaining an annual manufacturing potential of 30,000 units. Furthermore, the manufacturing facility has a expert checking out line and a complete first-rate system, licensed below ISO9001, to make sure the satisfactory of each forklift and supply clients with fine pleasant and first-rate service.

BYD Forklift has constantly aimed to create a main international manufacturer in electric powered forklifts. 'Pursuing excellence and non-stop innovation' is the improvement philosophy of BYD Forklift, consistently optimizing and upgrading its products, overlaying a ideal vary of purposes from warehousing and logistics to port and terminal logistics. The market enlargement consists of a couple of industries such as pharmaceuticals, food, bloodless chain processing, cosmetics, logistics, and more. In the manner of market feedback, BYD electric powered forklifts have wholly confirmed their extensive benefits in inexperienced environmental safety and power efficiency, receiving unanimous reward from clients at domestic and abroad, laying a strong basis for BYD electric powered forklifts to turn out to be a globally depended on brand.

In response to market improvement needs, BYD Forklift is setting up a complete electric powered forklift base in the Ningbo Industrial Park, integrating lookup and development, production, sales, and after-sales service. After completion, the challenge will be situated in the Yangtze River Delta, masking East China and radiating nationwide and for export. The deliberate whole funding for BYD Forklift's Ningbo manufacturing unit is five hundred million RMB, which will consist of a 60,000 rectangular meters facility encompassing procedures such as car machining, welding, painting, assembly, and modification, with the potential to produce 20,000 electric powered counterbalance forklifts and 30,000 warehouse forklifts annually.

Customer visit:

Before conducting consumer visits, the income or purchaser carrier groups usually time table appointments with clients and format the visit's timing, location, and agenda. This is achieved thru smartphone calls, emails, or different verbal exchange methods. The income or consumer carrier groups do specify the subjects to be mentioned with the customers, which consist of product presentations, difficulty resolution, training, commercial enterprise negotiations, or contract signings, amongst others. BYD’s patron carrier groups commonly put together applicable files and presentation substances to share with clients which might also encompass product manuals, presentation slides, samples, and more.

After the go to concludes, BYD’s income or client carrier groups generally record the meeting's content, dialogue outcomes, and plans for the subsequent steps. We additionally hold ongoing verbal exchange with clients to make certain their desires are met

FAQ:

1. Q: What is a BYD managing robot?

A: BYD coping with robotic is an independent navigation robotic designed for the managing and transportation of goods. They are outfitted with a number sensors and navigation technologies, permitting them to autonomously execute dealing with duties in environments such as factories, warehouses, and logistics centers.

2. Q: What kinds of items can BYD coping with robots handle?

A: BYD managing robots can take care of quite a number kinds of goods, such as uncooked materials, completed products, semi-finished products, objects on shelves, scientific equipment, meals and beverages, and more.

3. Q: How do these robots navigate and keep away from obstacles?

A: BYD coping with robots normally use a range of sensors, inclusive of laser radar, cameras, and ultrasonic sensors, to become aware of their surroundings. They create real-time maps and observe obstacles, permitting them to autonomously navigate and sketch paths to keep away from obstacles.

4. Q: What is the lifting capability of BYD dealing with robots?

A: The lifting capability of BYD coping with robots varies relying on the mannequin and configuration. Different fashions can deal with exclusive weights of goods, normally ranging from heaps of kilograms to a number of tons.

5. Q: How do these robots charge?

A: BYD managing robots are usually outfitted with batteries for power, and they can be charged the usage of charging equipment. Charging time and vary rely on the battery ability and model.

6. Q: Is human intervention required to function these robots?

A: BYD dealing with robots are computerized and generally do now not require human intervention. They can autonomously execute coping with duties primarily based on predefined missions however can additionally be monitored and operated remotely if needed.

7. Q: Does BYD supply after-sales carrier and preservation support?

A:Yes, BYD usually presents after-sales carrier and preservation support, which includes everyday maintenance, troubleshooting, and training.

8. Q: How do these robots beautify operational safety?

A: BYD managing robots are typically outfitted with more than a few security features, consisting of collision avoidance sensors, emergency give up devices, sound and mild alarms, to make certain protection at some point of operation.