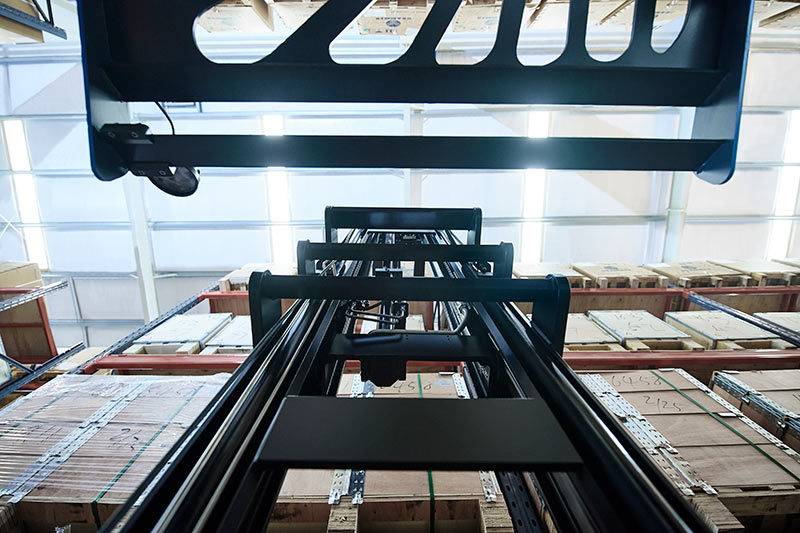

Four Wheel Electric Forklift ECB40

1.Attractive Styling: Departing from the traditional bulky design of forklifts, this forklift places importance on the harmony and unity of its body lines, focusing on visual enjoyment of the entire vehicle. With a streamlined design, it creates a stylish profile, showcasing a unique and dynamic personality.

2.Powerful Performance: Equipped with a high-performance drive axle and dual-drive high-power motors, with a total power of 2x15 kW, it delivers outstanding driving force. The vehicle efficiently outputs power, effortlessly tackling challenging terrains.

3.Exceptional Endurance: Featuring BYD's 100% self-developed lithium iron phosphate battery, it can achieve rapid charging in just 1 hour, meeting the demands of round-the-clock operations, accompanying you for 24 hours.

Product description:

The BYD ECB40 is an electric truck with a maximum workload of 4Ton designed to improve the day-to-day work of its operators. An ergonomic machine with lithium iron phosphate technology which is the one which differentiates BYD Forklift because it is more efficient, safer, cleaner, and has a longer lifespan than other trucks.

Product Parameter:

Identification | 1.1 | Manufacturer | BYD | ||

1.2 | Model | ECB40 | |||

1.3 | Drive | Electric | |||

1.4 | Operator type | Seat | |||

1.5 | Rated capacity | Q | kg | 4000 | |

1.6 | Load center | c | mm | 500 | |

1.8 | Load distance, center of drive axle to fork | x | mm | 555 | |

1.9 | Wheelbase | y | mm | 2000 | |

weight | 2.1 | Service weight | kg | 6750 | |

2.2 | Axle load, with load, front/rear | kg | 9440/1310 | ||

2.3 | Axle load, without load, front/rear | kg | 3330/3420 | ||

Wheels, Chassis

| 3.1 | Tyres | SE | ||

3.2 | Tyre size, front | 28/12.5-15 | |||

3.3 | Tyre size, rear | 2×/8-9 | |||

3.5 | Wheels, number front rear (x=driven wheels) | 2×/2 | |||

3.6 | Track width, front | b10 | mm | 1216 | |

3.7 | Track width, rear | b11 | mm | 1130 | |

Basic dimensions | 4.1 | Tilt of mast/fork carriage forward/backward | a/b | deg | 6/8 |

4.2 | Height, mast lowered | h2 | mm | 2350 | |

4.3 | Free lift | h2 | mm | 130 | |

4.4 | Lift height | h3 | mm | 3000 | |

4.5 | Height, mast extended | h4 | mm | 4255 | |

4.7 | Height of overhead guard | h6 | mm | 2360 | |

4.8 | Seat height | h7 | mm | 1260 | |

4.12 | Coupling height | h20 | mm | 490 | |

4.19 | Overall length | l1 | mm | 3990 | |

4.20 | Length to face of forks | l2 | mm | 2920 | |

4.21 | Overall width | b1 | mm | 1516 | |

4.22 | Fork dimensions | s/e/l | mm | 50/150/1070 | |

4.23 | Fork carriage ISO 2328,class/type A,B | 3A | |||

4.24 | Fork carriage width | b3 | mm | 1500 | |

4.31 | Ground clearance, with load, below mast | m1 | mm | 150 | |

4.32 | Ground clearance, center of wheelbase | m2 | mm | 160 | |

4.33 | Aisle width of pallets 1000×1200 crossways | Ast | mm | 4355 | |

4.34 | Aisle width of pallets 800×1200 lengthways | Ast | mm | 4555 | |

4.35 | Turning radius | Wa | mm | 2600 | |

Performance Data | 5.1 | Travel speed, with/without load | Km/h | 18/18 | |

5.2 | Lift speed, with/without load | mm/s | 350/450 | ||

5.3 | Lowering speed, with/without load | mm/s | 500/400 | ||

5.6 | Max. drawbar pull, with/without load | KN | 23/18 | ||

5.8 | Max. gradeability, with/without load | % | 15/20 | ||

5.10 | Service brake | Hydr. | |||

Motor | 6.1 | Drive motor rating S2 60 min. | kW | 15×2 | |

6.2 | Lift motor rating at S3 15% | kW | 25.4 | ||

6.4 | Battery voltage, nominal capacity K5 | V/Ah | 80/810 | ||

6.5 | Battery weight | kg | 900 | ||

Others

| 8.1 | Type of drive control | AC | ||

8.2 | Operating pressure for attachments | Bar | 170 | ||

8.4 | Sound level at the driver’s ear | dB(A) | ≤75 | ||

8.5 | Towing coupling, type | PIN |

Mast specifications:

h3 Lifting Height(mm) h2 Full Free Lift Height(mm) h2 Height, Mast Full Lowered(mm) h4 Height, Mast Full Extended(mm)(Load Backrest 1000mm) α Tilt Forward β Tilt Backward

Mast Specifications(mm) | h3 | h2 | h2 | h4 | α | β | Residual Capacity(kg) (without attachment) |

ECB40@500MM | |||||||

2-stage standard Mast

| 3000 | 140 | 2350 | 4250 | 6° | 8° | 4000 |

3300 | 140 | 2500 | 4550 | 6° | 8° | 4000 | |

3500 | 140 | 2600 | 4750 | 6° | 8° | 4000 | |

4000 | 140 | 2850 | 5250 | 6° | 8° | 4000 | |

4500 | 140 | 3100 | 5750 | 6° | 6° | 3800 | |

5000 | 140 | 3350 | 6250 | 6° | 6° | 3600 | |

6000 | 140 | 3850 | 7250 | 6° | 6° | 3200 | |

2-stage FFL Mast | 3000 | 1035 | 2235 | 4250 | 6° | 8° | 4000 |

3300 | 1185 | 2385 | 4550 | 6° | 8° | 4000 | |

3500 | 1285 | 2485 | 4750 | 6° | 8° | 4000 | |

4000 | 1585 | 2785 | 5250 | 6° | 8° | 4000 | |

4000 | 945 | 2145 | 5250 | 6° | 6° | 3900 | |

3-stage with single FFL | 4300 | 1045 | 2245 | 5550 | 6° | 6° | 3800 |

4500 | 1115 | 2315 | 5750 | 6° | 6° | 3700 | |

4800 | 1215 | 2415 | 6050 | 6° | 6° | 3600 | |

5000 | 1285 | 2485 | 6250 | 6° | 6° | 3500 | |

5500 | 1445 | 2645 | 6750 | 6° | 6° | 3300 | |

6000 | 1615 | 2815 | 7050 | 6° | 6° | 3100 | |

6500 | 1785 | 2985 | 7750 | 6° | 3° | 2900 | |

6800 | 1885 | 3085 | 8050 | 6° | 3° | 2800 | |

7200 | 2065 | 3265 | 8450 | 3° | 3° | 2600 | |

7500 | 2165 | 3365 | 8750 | 3° | 3° | 2500 |

Classification:

1.Multi-function armrest with fingertip control

2.Seat with full suspension

3.Mast with full free double lifting cylinders

4.Curve speed adjustment to improve stability and reduce risk of overturning

5.Brake assist when it detects that the operator is releasing the brake on a ramp or slope

6.Limitation of the front tilt angle to reduce the risk of load drop

7.When the load exceeds 10% of the set weight, the engine stops working for safety’s sake

8.Multifunction TFT display with scrolling speed, remaining battery capacity, clock with working hours and accumulated hours, and three speed modes

Optional configuration:

1.Reverse voice warning

2.Reverse horn

3.Flashing light

4.Front blue light

5.Rear blue light

6.Work lighting (rear)

7.Blue laser light

8.Panoramic rearview mirror

9.Fan

10.Fire extinguisher

11.Special key (single-point ignition switch)

12.Simple canopy

13.Enclosed cabin

14.400A charger

15.Environmentally friendly tires

16.Customized door frame

17.Customized cargo guard

18.Customized fork arms

Use:

Manufacturing, Paper Industry, Automotive Industry, Feed Industry, Household Appliance, Logistics, Food and Beverage

Product advantages:

1.Attractive Styling: Departing from the traditional bulky design of forklifts, this forklift places importance on the harmony and unity of its body lines, focusing on visual enjoyment of the entire vehicle. With a streamlined design, it creates a stylish profile, showcasing a unique and dynamic personality.

2.Powerful Performance: Equipped with a high-performance drive axle and dual-drive high-power motors, with a total power of 2x15 kW, it delivers outstanding driving force. The vehicle efficiently outputs power, effortlessly tackling challenging terrains.

3.Exceptional Endurance: Featuring BYD's 100% self-developed lithium iron phosphate battery, it can achieve rapid charging in just 1 hour, meeting the demands of round-the-clock operations, accompanying you for 24 hours.

4.Extended Warranty: We offer an industry-leading warranty: 5 years or 12,000 hours for the battery, ensuring true peace of mind for our customers.

5.Superior Handling: The fingertip control system with an electronic proportional valve is within easy reach, providing flexibility and convenience. It can be configured with dual joysticks and dual pedals, allowing for 360° operation without blind spots, ensuring smooth movement.

6.Human-Machine Engineering: A mechanically suspended seat with OPS function ensures safety and comfort. The spacious leg workspace, clear and expansive upper and front views, large reverse assist handle make operation effortless and comfortable. The multifunctional color display panel provides clear vehicle information at a glance.

Product inspection:

BYD forklift manufacturers usually carry out strict product inspection and quality control when producing forklift products to ensure that the quality and performance of the products reach high standards. These product inspections start with the inspection of raw materials: in the production process, BYD checks the raw materials used. This includes checking steel, electronic components, lubricants, coatings, etc. Raw materials must meet specific quality standards and specifications.

Manufacturing process inspection: During the manufacturing process of the forklift, BYD monitors and inspects key process steps to ensure that each component meets the design specifications. This includes inspections of welding, machining, electrical connections and other aspects.

Performance Testing: After the forklift is assembled, performance testing is conducted. This includes checking engine power, suspension systems, brake systems, driver control systems, and more to ensure that the forklift's performance meets specified standards.

Safety Testing: BYD forklifts undergo safety testing to ensure compliance with relevant safety standards. This includes collision tests, stability tests, electrical safety tests, and others.

Quality control: BYD implements a quality control system, including inspection and testing procedures, documentation, staff training, etc., to ensure the consistency and quality of products.

Final Inspection: After the completion of forklift production, a final inspection is performed. This involves a comprehensive check of the entire forklift to ensure that all components are installed correctly, there are no obvious defects, and performance is excellent.

Product Certification: Once the forklifts pass all necessary inspections and tests, they may receive relevant product certifications to prove compliance with international and regional quality and safety standards.

Packaging and transportation:

The packaging and transportation of BYD forklifts are typically handled by the BYD’s manufacturer and suppliers to ensure that the products are not damaged during transit.

Packaging: Forklifts are usually packaged before leaving the factory to protect their appearance and mechanical components from damage.Packaging usually involves the use of wooden cases, foam stuffing, plastic film, and strapping straps to ensure that the forklift is free from bumps and collisions during transportation.

Inspection and Testing: Before leaving the factory, manufacturers typically conduct rigorous inspections and testing on the forklifts to ensure that they function properly and can be safely transported. This includes checking mechanical components, batteries, brake systems, and more.

Transport: Once the forklift is packed and passed inspection, it is ready for transport. Depending on the distance, region or country and customer requirements, forklifts can be transported to the destination by road, sea, air or other means.

Documentation and Permits: Depending on the requirements of the destination country or region, relevant documents and permits may need to be provided to ensure that the forklifts can legally enter and be used in the destination country or region.

Company introduction:

Founded in 2009, BYD Forklift is a subsidiary of BYD Co., LTD., located in Zhenjiang District, Shaoguan. The total investment of the project is 515 million yuan, covering an area of about 700,000 square meters. Mainly responsible for the production of BYD electric forklift series, including electric balance forklift series, electric storage forklift series, electric trailer series, etc.

BYD forklift has a complete forklift production line, including 4 processing and welding lines, 1 painting line and 3 final assembly lines, with an annual production capacity of 30,000 units. In addition, the factory has a professional inspection line and a comprehensive quality system, through the ISO9001 certification, to ensure the quality of each forklift, to provide customers with satisfactory quality and excellent service.

BYD Forklift has always aimed to create a leading global brand in electric forklifts. 'Pursuing excellence and continuous innovation' is the development philosophy of BYD Forklift, continuously optimizing and upgrading its products, covering a perfect range of applications from warehousing and logistics to port and terminal logistics. The market expansion includes multiple industries such as pharmaceuticals, food, cold chain processing, cosmetics, logistics, and more. In the process of market feedback, BYD electric forklifts have fully demonstrated their significant advantages in green environmental protection and energy efficiency, receiving unanimous praise from customers at home and abroad, laying a solid foundation for BYD electric forklifts to become a globally trusted brand.

In response to market development needs, BYD Forklift is constructing a comprehensive electric forklift base in the Ningbo Industrial Park, integrating research and development, production, sales, and after-sales service. After completion, the project will be centered in the Yangtze River Delta, covering East China and radiating nationwide and for export. The planned total investment for BYD Forklift's Ningbo factory is 500 million RMB, which will include a 60,000 square meters facility encompassing processes such as vehicle machining, welding, painting, assembly, and modification, with the capacity to produce 20,000 electric counterbalance forklifts and 30,000 warehouse forklifts annually.

Customer visit:

Before conducting customer visits, the sales or customer service teams typically schedule appointments with customers and plan the visit's timing, location, and agenda. This is done through phone calls, emails, or other communication methods. The sales or customer service teams do specify the topics to be discussed with the customers, which include product presentations, issue resolution, training, business negotiations, or contract signings, among others. BYD’s customer service teams usually prepare relevant documents and presentation materials to share with customers which may include product manuals, presentation slides, samples, and more.

After the visit concludes, BYD’s sales or customer service teams typically document the meeting's content, discussion outcomes, and plans for the next steps. We also maintain ongoing communication with customers to ensure their needs are met

FAQ:

1. Q: Does BYD forklifts provide after-sales service?

A: Yes, BYD offers comprehensive after-sales services, including maintenance, spare parts supply, training, and technical support, to ensure that customers' forklifts remain in optimal condition.

2. Q: Does BYD forklifts offer customization options?

A: Yes, BYD typically provides customization options to meet specific customer requirements. You can get in touch with their sales team to discuss the possibilities of customizing a forklift.

3. Question: Do BYD electric forklifts comply with international standards and certifications?

Answer: Yes, BYD electric forklifts typically conform to international safety and quality standards and obtain relevant certifications. This includes CE certification, ISO certification, and more, to ensure the legality and quality of the products in international markets.

4. Question: Can BYD electric forklifts adapt to different power standards?

Answer: Yes, BYD electric forklifts usually have multi-power compatibility and can adapt to different countries' and regions' power standards and voltages. This allows them to be used globally.

5. Question: Are BYD electric forklifts suitable for indoor and outdoor use?

Answer: Yes, BYD electric forklifts are suitable for both indoor and outdoor use. Their design typically includes features that adapt to various working environments, including indoor warehousing and outdoor logistics operations.

6. Question: What is the range or battery life of BYD electric forklifts?

Answer: The range or battery life of BYD electric forklifts depends on the specific model and battery capacity. BYD electric forklifts usually offer adjustable battery capacities to meet various application needs. The range or battery life is typically specified in the product specifications.