Low Profile Mini Pallet Jack

Efficient and bendy operation: New manage configuration that permits for upright on foot of the handle, saving steerage space; at the identical time, bendy sketch allows speedy and handy battery replacement, bettering work efficiency.

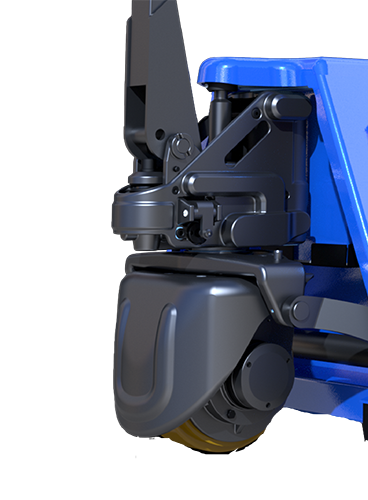

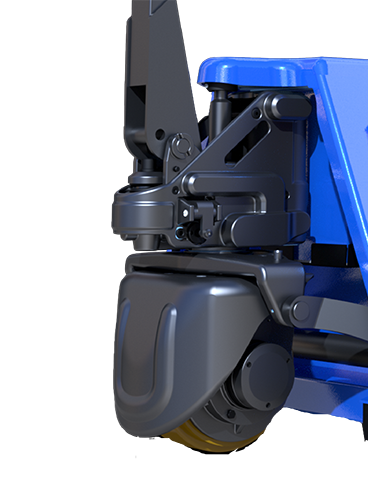

Flexible operation: Small turning radius makes the forklift extra bendy when navigating via slim and curved areas or bypassing obstacles; comfy working deal with significantly enhances operational flexibility; each lifting and urgent down on the take care of can observe brakes, making sure effectivity and safety.

High safety: Features finest slope braking performance, highlighting the strong mountaineering capability of BYD's micro pallet managing car whilst retaining stability; geared up with a couple of features together with overload protection, hill-hold protection, low battery protection, etc.

Outstanding performance: Equipped with world-class battery cells, assembled as a pack, supplying dependable energy provide for the complete vehicle.

Product description:

Thanks to BYD Mini 15 for micro electric transport vehicle which has enhanced safety and smooth transportation of goods.

Product Parameter:

Identification | 1.1 | Manufacturer | BYD | ||

1.2 | Model | Mini 15 | |||

1.3 | Drive | Electric | |||

1.4 | Operator type | Pedestrian | |||

1.5 | Load capacity | kg | 1500 | ||

Weight | 2.1 | Service weight (including battery) | kg | 120 | |

Wheels | Tyre | PU | |||

Dimensions | 4.9 | Tiller height,min/max.positon | 460/1220 | ||

4.15 | Fork height lowered | mm | 80 | ||

4.19 | Overall length | mm | 1555/1625 | ||

4.20 | Overall length(without fork) | mm | 405 | ||

4.21 | Overall width | mm | 540 | ||

4.22 | Fork dimension | mm | 53/160/1150 | ||

4.25 | Width overall fork | mm | 540 | ||

4.35 | Minimum Turning radius | Wa | mm | 1352 | |

Performance Data | 5.1 | Travel speed, with/without load | mm/s | 4.5/5 | |

5.8 | Max. Gradeability with/ without load | % | 8/20 | ||

5.10 | Service brake | Electromagnetic | |||

Type of drive | DC brushed | ||||

Lift motor type | DC brushed | ||||

Battery voltage/capacity | V/Ah | 24/20 | |||

Battery weight | kg | 3.5 |

Features :

Anti-slip power wheels

Dual-wheel load-bearing

Customized forks

100A charger (REMA socket)

100A charger (national fashionable socket)

30A onboard charger

Use:

Warehousing and Logistics industry, Factory and manufacturing industry, Commercial and retail industry, Food and beverage industry, Medical amenities industry, agriculture, Large scale development site.

Product advantages:

Efficient and bendy operation: New deal with configuration that permits for upright strolling of the handle, saving guidance space; at the equal time, bendy graph permits rapid and effortless battery replacement, bettering work efficiency.

Flexible operation: Small turning radius makes the forklift extra bendy when navigating via slim and curved areas or bypassing obstacles; comfy working manage appreciably enhances operational flexibility; each lifting and urgent down on the cope with can practice brakes, making sure effectivity and safety.

High safety: Features ideal slope braking performance, highlighting the sturdy hiking capacity of BYD's micro pallet dealing with car whilst preserving stability; outfitted with a couple of features consisting of overload protection, hill-hold protection, low battery protection, etc.

Outstanding performance: Equipped with world-class battery cells, assembled as a pack, imparting dependable energy furnish for the complete vehicle.

Product inspection:

BYD forklift manufacturer typically conducts rigorous product inspections and quality control when producing forklift products to ensure that their quality and performance meet high standards. These product inspects starts as from Raw Material Inspection: During the production process, BYD inspects the raw materials used. This includes checking steel, electronic components, lubricants, coatings, and more. Raw materials must meet specific quality standards and specifications.

Manufacturing Process Inspection: During the forklift's manufacturing process, BYD monitors and inspects key process steps to ensure that each component meets design specifications. This includes inspections of welding, mechanical processing, electrical connections, and other aspects.

Performance Testing: After the forklift is assembled, performance testing is conducted. This includes checking engine power, suspension systems, brake systems, driver control systems, and more to ensure that the forklift's performance meets specified standards.

Safety Testing: BYD forklifts undergo safety testing to ensure compliance with relevant safety standards. This includes collision tests, stability tests, electrical safety tests, and others.

Quality Control: BYD implements a quality control system, including inspection and testing procedures, document records, employee training, and more, to ensure product consistency and quality.

Final Inspection: After the completion of forklift production, a final inspection is performed. This involves a comprehensive check of the entire forklift to ensure that all components are installed correctly, there are no obvious defects, and performance is excellent.

Product Certification: Once the forklifts pass all necessary inspections and tests, they may receive relevant product certifications to prove compliance with international and regional quality and safety standards.

Packaging and transportation:

The packaging and transportation of forklifts are typically handled by the manufacturer and suppliers to ensure that the products are not damaged during transit.

Packaging: Forklifts are usually packaged before leaving the factory to protect their appearance and mechanical components from damage. Packaging typically includes the use of wooden crates, foam padding, plastic film, and strapping materials to ensure that the forklifts are not affected by bumps and collisions during transportation.

Inspection and Testing: Before leaving the factory, manufacturers typically conduct rigorous inspections and testing on the forklifts to ensure that they function properly and can be safely transported. This includes checking mechanical components, batteries, brake systems, and more.

Shipping: Once the forklifts are properly packaged and pass inspection, they are prepared for shipping. Forklifts can be transported to their destination via road transportation, sea shipping, air freight, or other methods, depending on the distance, region or country and customer requirements.

Documentation and Permits: Depending on the requirements of the destination country or region, relevant documents and permits may need to be provided to ensure that the forklifts can legally enter and be used in the destination country or region.

Company introduction:

BYD Forklift, established in 2009, is a subsidiary of BYD Co., Ltd., located in the Zhenjiang district of Shaoguan City. The total investment for the project is 515 million RMB, covering an area of approximately 700,000 square meters. It is mainly responsible for producing BYD electric forklift series, including the electric counterbalance forklift series, electric warehouse forklift series, and electric tow tractor series, among others.

BYD Forklift possesses a complete forklift production line, including four machining and welding lines, one painting line, and three final assembly lines, achieving an annual production capacity of 30,000 units. Furthermore, the factory has a professional testing line and a comprehensive quality system, certified under ISO9001, to ensure the quality of every forklift and provide customers with satisfactory quality and excellent service.

BYD Forklift has always aimed to create a leading global brand in electric forklifts. 'Pursuing excellence and continuous innovation' is the development philosophy of BYD Forklift, continuously optimizing and upgrading its products, covering a perfect range of applications from warehousing and logistics to port and terminal logistics. The market expansion includes multiple industries such as pharmaceuticals, food, cold chain processing, cosmetics, logistics, and more. In the process of market feedback, BYD electric forklifts have fully demonstrated their significant advantages in green environmental protection and energy efficiency, receiving unanimous praise from customers at home and abroad, laying a solid foundation for BYD electric forklifts to become a globally trusted brand.

In response to market development needs, BYD Forklift is constructing a comprehensive electric forklift base in the Ningbo Industrial Park, integrating research and development, production, sales, and after-sales service. After completion, the project will be centered in the Yangtze River Delta, covering East China and radiating nationwide and for export. The planned total investment for BYD Forklift's Ningbo factory is 500 million RMB, which will include a 60,000 square meters facility encompassing processes such as vehicle machining, welding, painting, assembly, and modification, with the capacity to produce 20,000 electric counterbalance forklifts and 30,000 warehouse forklifts annually.

Customer visit:

Before conducting customer visits, the sales or customer service teams typically schedule appointments with customers and plan the visit's timing, location, and agenda. This is done through phone calls, emails, or other communication methods. The sales or customer service teams do specify the topics to be discussed with the customers, which include product presentations, issue resolution, training, business negotiations, or contract signings, among others. BYD’s customer service teams usually prepare relevant documents and presentation materials to share with customers which may include product manuals, presentation slides, samples, and more.

After the visit concludes, BYD’s sales or customer service teams typically document the meeting's content, discussion outcomes, and plans for the next steps. We also maintain ongoing communication with customers to ensure their needs are met

FAQ:

1. Q: What is a BYD mini forklift?

A: BYD mini forklift is a small electric forklift typically used for material handling and transport tasks in warehouses, factories, logistics centers, and similar settings. They typically have compact dimensions and electric power, making it easy to move and transport goods.

2. Q: What is the load capacity of BYD mini forklifts?

A: The load capacity of BYD mini forklifts can vary depending on the model and usually ranges from 500 kilograms to 2000 kilograms. Different models of forklifts may be suitable for different types of material handling tasks.

3. Q: What type of power source do BYD mini forklifts use?

A: Most BYD mini forklifts use electric power, often powered by lithium-ion batteries.