Sit Down Truck Forklift RTR16

Rapid Charging Capability: Equipped with an 80V/270A battery, it is well-suited for prolonged operations and can be without difficulty charged the usage of the countrywide widespread charging port, making sure convenience, efficiency, and safety.

Effortless Operation: The instrument panel gives real-time data, consisting of lifting height, steerage angle, and cargo weight, streamlining the operation for most ease.

Enhanced Safety Features: With an offset-free cylinder design, it affords a broader driver's subject of vision. The gantry contains cushioning performance inside the eight to 8.5-meter lifting top range. It additionally consists of OPS seats, overload protection, high-angle tilt protection, and energy-regenerative braking, prioritizing safety.

Impressive Performance: Featuring superior batteries, motors, and digital controls, it boasts a effective powertrain that meets the needs of stacking and coping with warehouse goods, considerably enhancing warehousing logistics efficiency.

Product description:

Introducing the BYD RTR16 model, the inaugural Reach Truck to be part of the BYD product lineup, boasting brand new layout that harmonizes with most excellent riding comfort, safety, and work efficiency. Fueled with the aid of BYD's lithium iron-phosphate technology, it showcases an superior battery administration machine with the industry's lengthiest warranty: eight years or 10,000 hours, whichever happens first.

Product Parameter:

Identification | 1.1 | Manufacturer | BYD | ||

1.2 | Model | RTR16 | |||

1.3 | Drive | Electric | |||

1.4 | Operator type | Seated | |||

1.5 | Rated capacity | Q | kg | 1600 | |

1.6 | Load center | C | mm | 600 | |

1.8 | Load distance, center of drive axle to fork | X | mm | 188/400 | |

1.9 | Wheelbase | Y | mm | 1470 | |

Weight | 2.1 | Net weight including battery | kg | 4070 | |

2.3 | Axle loading, fork advanced,laden front/rear | kg | 1909/2361 | ||

2.4 | Axle loading, unladen front/rear | kg | 1038/4832 | ||

2.5 | Axle loading, fork retracted, laden front/rear | kg | 2627/1643 | ||

Wheels

| 3.1 | Wheel type | PU | ||

3.2 | Tyre size, front | mm | ∅343×136 | ||

3.3 | Tyre size, rear | mm | ∅340×100 | ||

3.5 | Wheels, number front rear (x=driven wheels) | 1x/2 | |||

3.7 | Tread width, rear | b11 | mm | 1170 | |

Dimensions | 4.1 | Tilt of mast/fork carriage forward/backward | α/β | (°) | 2/4 |

4.2 | Mast height(lowered) | h2 | mm | 3496 | |

4.3 | Free lift | h2 | mm | 2250 | |

4.4 | Lift height | h3 | mm | 8500 | |

4.5 | Extended mast height | h4 | mm | 9746 | |

4.7 | Height of overhead guard | h6 | mm | 2345 | |

4.8 | Seat height/standing height | h7 | mm | 1020 | |

4.10 | Height of support arms | h8 | mm | 360 | |

4.19 | Overall length | l1 | mm | 2555 | |

4.20 | Length to the face of forks | l2 | mm | 1355 | |

4.21 | Overall width | b1 | mm | 1270 | |

4.22 | Fork dimensions | s/e/l | mm | 35×100×1200 | |

4.23 | Fork carriage ISO 2328, class/type A,B | 2A | |||

4.24 | Fork carriage width | b3 | mm | 730 | |

4.25 | Width across fork | b5 | mm | 430/678 | |

4.26 | Width between support arms/loading areas | b4 | mm | 930 | |

4.28 | Reach distance | l4 | mm | 588 | |

4.31 | Ground clearance, under the mast | m1 | mm | 73 | |

4.32 | Ground clearance, center of wheelbase | m2 | mm | 80 | |

4.33 | Aisle width for pallets 1000×1200 crossways | Ast | mm | 2848 | |

4.34 | Aisle width of pallets 800×1200 lengthways | Ast | mm | 2904 | |

4.35 | Turning radius | Wa | mm | 1758 | |

4.37 | Length across support arms | l7 | mm | 1930 | |

Performance Data | 5.1 | Travel speed, with/without load | Km/h | 13/13 | |

5.2 | Lift speed, with/without load | mm/s | 380/680 | ||

5.3 | Lowering speed, with/without load | mm/s | 550/550 | ||

5.4 | Mast reaching speed, with/without load | mm/s | 180/180 | ||

5.4a | Mast retracting speed, with/without load | mm/s | 180/180 | ||

5.8 | Max. gradeability, with/without load | % | 12/12 | ||

5.9 | Acceleration time, with/without load (0-10mm) | 5.6/5.0 | |||

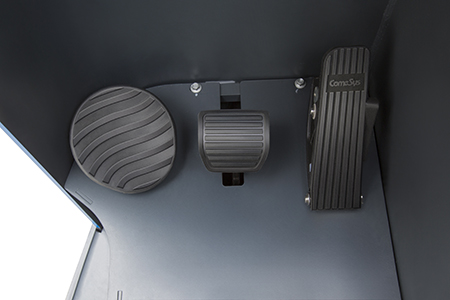

5.10 | Service brake | Hydraulic/Mechanic | |||

Electric Motor | 6.1 | Drive motor rating S2 60 min. | kW | 6.8/13.2 | |

6.2 | Lift motor rating at S3 15% | kW | 12/19 | ||

6.4 | Battery voltage/nominal capacity K5 | V/Ah | 80/270 | ||

6.5 | Battery weight | kg | 425 | ||

8.1 | Type of drive control | AC | |||

8.2 | Operating pressure for attachments | bar | 210 | ||

8.4 | Sound level at the driver’s ear | dB(A) | ≤75 |

Classification:

BYD Iron-Phosphate Technology

Battery 80V 270Ah (21.6 kWh)

AC drive

4-way valve

Fork tilting

Hook-on side-shifter

Finger-tip control

TFT display

Cornering pace reduction

OPS (Operator Presence Sensor)

Regenerative braking system

Load wheel brake

Charger 80V 100A

2-hour charging time

Adjustable steerage wheel

Orange seat belt with sensor

Optional configuration:

1-hour fast-charging solution

Charger 80V 200A

Fork digital camera system

Load weight indicator

Overload protection

Height display

Laser light

High stage velocity limit

Blue light

Panoramic mirror

Rear working light

Second-level Fully Articulated

Third-level Fully Articulated Mast

Speed discount with mast lifted

Customized Forks

Use:

Warehousing and Logistics industry, manufacturing industry, retail industry, electronics industry, food and beverage industry, pharmaceutical industry, agriculture.

Product advantages:

Rapid Charging Capability: Equipped with an 80V/270A battery, it is well-suited for prolonged operations and can be without difficulty charged the usage of the countrywide wellknown charging port, making sure convenience, efficiency, and safety.

Effortless Operation: The instrument panel presents real-time data, which includes lifting height, guidance angle, and cargo weight, streamlining the operation for most ease.

Enhanced Safety Features: With an offset-free cylinder design, it provides a broader driver's area of vision. The gantry contains cushioning performance inside the eight to 8.5-meter lifting peak range. It additionally consists of OPS seats, overload protection, high-angle tilt protection, and energy-regenerative braking, prioritizing safety.

Impressive Performance: Featuring superior batteries, motors, and digital controls, it boasts a effective powertrain that meets the needs of stacking and dealing with warehouse goods, substantially enhancing warehousing logistics efficiency.

Product inspection:

BYD Forklift, as a manufacturer, diligently conducts vast product inspections and enforces stringent first-class manipulate measures in the course of the manufacturing of forklifts, making sure that every unit meets fairly excessive requirements of best and performance. This rigorous great assurance procedure starts offevolved with Raw Material Inspection, the place BYD meticulously examines the uncooked substances employed in production, encompassing steel, digital components, lubricants, coatings, and more. These uncooked substances ought to adhere to specific first-rate requirements and specifications.

Furthermore, the Manufacturing Process Inspection includes non-stop monitoring and scrutiny of imperative manufacturing steps to make certain that each thing conforms to format specifications. This consists of meticulous inspections of welding, mechanical processing, electrical connections, and quite a number different elements of production.

Upon meeting completion, BYD conducts complete Performance Testing to investigate the forklift's engine power, suspension systems, brake systems, driver manipulate systems, and more. This rigorous contrast ensures that the forklift's overall performance aligns with precise standards.

Safety is a paramount concern, prompting BYD to situation its forklifts to rigorous Safety Testing, encompassing collision tests, steadiness assessments, electrical security examinations, and a range of different safety-related reviews to meet and exceed applicable protection standards.

To hold product consistency and excellence, BYD implements a complete Quality Control machine that consists of inspection and trying out protocols, meticulous documentation, worker training, and a variety of different measures.

The Final Inspection, carried out post-production, entails a thorough examination of each and every factor of the forklift to make sure particular thing installation, absence of any evident defects, and top-notch performance.

Following profitable completion of all requisite inspections and tests, forklifts may also earn applicable product certifications, serving as testomony to their compliance with worldwide and regional high-quality and protection standards.

Packaging and transportation:

The producer and suppliers generally take accountability for the packaging and transportation of forklifts to make certain that these merchandise continue to be undamaged for the duration of transit.

Packaging: To shield the look and mechanical factors of forklifts from any conceivable harm, it is common to package deal them earlier than they depart the factory. This packaging manner frequently comprises the use of protecting substances such as wood crates, foam padding, plastic film, and sturdy strapping materials, all of which are employed to protect the forklifts from impacts, bumps, and collisions that may also show up in the course of transportation.

Inspection and Testing: Before forklifts embark on their experience from the factory, producers meticulously concern them to rigorous inspections and complete testing. The purpose is to assurance that each component of the forklift features efficiently and that they are in shape for protected transportation. This complete contrast consists of scrutiny of mechanical components, batteries, brake systems, and quite a number different necessary elements.

Shipping: Once the forklifts are securely packaged and have effectively surpassed the stringent inspections, they are organized for shipping. The preference of transportation mode for the forklifts relies upon on elements such as distance, destination, regional requirements, and purchaser preferences. Options may also consist of street transportation, sea shipping, air freight, or different appropriate strategies to make sure a protected and well timed delivery.

Documentation and Permits: To make sure compliance with the rules and stipulations of the vacation spot united states of america or region, the producer and suppliers might also want to furnish applicable archives and permits. This vital step ensures that the forklifts are legally authorised to enter and function inside the vacation spot usa or region, thereby facilitating a easy and lawful transportation process.

Company introduction:

BYD Forklift, a subsidiary of BYD Co., Ltd., used to be installed in 2009 and is positioned in the Zhenjiang district of Shaoguan City. This formidable challenge boasts a tremendous funding of 515 million RMB and covers an expansive region spanning about 700,000 rectangular meters. The main focal point of BYD Forklift lies in the manufacturing of a complete vary of electric powered forklift series, which consists of the electric powered counterbalance forklift series, electric powered warehouse forklift series, and electric powered tow tractor series, amongst others.

BYD Forklift has meticulously developed a whole forklift manufacturing line that encompasses 4 machining and welding lines, in addition to one portray line and three last meeting lines. This complete setup permits the facility to attain an marvelous annual manufacturing capability of 30,000 units. Furthermore, the manufacturing facility has instituted a expert trying out line and carried out a complete pleasant system, securing ISO9001 certification. These measures are applied to make sure the impeccable high-quality of every forklift and to grant clients with a persistently excessive stage of pleasant and splendid service.

BYD Forklift has persistently pursued its imaginative and prescient of turning into a globally diagnosed chief in electric powered forklifts. The organization embraces a improvement philosophy founded round "Pursuing excellence and non-stop innovation." This dedication drives BYD Forklift to forever optimize and decorate its product offerings, catering to a numerous vary of functions spanning from warehousing and logistics to port and terminal logistics. Market growth efforts prolong throughout a couple of industries, inclusive of pharmaceuticals, food, bloodless chain processing, cosmetics, and a number of aspects of the logistics sector. In response to precious market feedback, BYD electric powered forklifts have pretty verified their vast benefits in inexperienced environmental safety and strength efficiency. These features have garnered unanimous reward from each home and worldwide customers, thereby setting up a company basis for BYD electric powered forklifts to emerge as a globally depended on brand.

In alignment with market improvement demands, BYD Forklift is presently in the procedure of setting up a complete electric powered forklift base inside the Ningbo Industrial Park. This forward-looking initiative integrates lookup and development, production, sales, and after-sales carrier to meet the evolving wants of the market. Upon completion, this challenge will serve as a central hub inside the Yangtze River Delta region, extending its attain to cowl East China whilst radiating across the complete state and past for export. The strategic design consists of a giant complete funding of five hundred million RMB, earmarked for the BYD Forklift Ningbo factory. This astounding facility spans 60,000 rectangular meters and encompasses a variety of critical strategies such as automobile machining, welding, painting, assembly, and modification. Its sturdy infrastructure will empower it to produce an annual output of 20,000 electric powered counterbalance forklifts and 30,000 warehouse forklifts, thereby contributing drastically to BYD Forklift's endured increase and success.

Customer visit:

In guidance for purchaser visits, the committed income and patron carrier groups at BYD proactively prepare appointments with consumers whilst meticulously coordinating the timing, location, and agenda of every visit. These preparations are successfully facilitated thru a range of verbal exchange channels, such as smartphone conversations, electronic mail correspondences, and different applicable capacity of contact. As section of this meticulous planning process, the income and patron provider groups intricately define the particular subjects that will be addressed at some stage in these interactions. These matters embody a vast array of subjects, inclusive of product presentations, problem decision strategies, education sessions, complex commercial enterprise negotiations, and, when applicable, the formal signing of contracts. To bolster the effectiveness of these engagements, BYD's purchaser provider groups diligently gather pertinent archives and presentation materials, which can also incorporate complete product manuals, illustrative presentation slides, tangible samples, and a host of extra assets designed to beautify the client experience.

Once the consumer go to has efficaciously concluded, BYD's adept income and patron carrier groups systematically report the meeting's proceedings. This meticulous documentation procedure comprehensively encompasses the content material mentioned all through the interaction, the effects of these discussions, and the strategic plans formulated for the subsequent steps in the client relationship. Beyond the preliminary visit, BYD locations vast emphasis on retaining an ongoing line of verbal exchange with purchasers to make certain that their evolving wants and necessities are constantly met and addressed with the utmost professionalism and dedication.

FAQ:

1. Q: What industries are BYD warehouse attain vans appropriate for?

A: BYD warehouse attain vans are normally appropriate for more than a few industries, consisting of warehousing and logistics, manufacturing, retail, electronics, meals and beverage, pharmaceuticals, and more. They are used for transporting, stacking, and storing goods, enhancing logistics efficiency.

2. Q: What are the one of a kind fashions and capacities of BYD warehouse attain trucks?

A: BYD provides a range of models and capacities for warehouse attain vans to meet the particular wants of extraordinary customers. The desire of mannequin and capability relies upon on particular utility necessities and working environments.

3. Q: What kind of electricity supply do BYD warehouse attain vans use?

A: BYD warehouse attain vans normally use batteries as their electricity source, which helps limit emissions, enhance power efficiency, and decrease noise.

4. Q: Is working BYD warehouse attain vehicles convenient to learn?

A: Operating BYD warehouse attain vehicles is usually extraordinarily handy to learn, however operators want to endure coaching and gain the applicable driver's license. BYD commonly gives education and academic substances to make sure that operators apprehend secure operation and high-quality practices.

5. Q: Do BYD warehouse attain vehicles come geared up with protection features?

A: Yes, BYD warehouse attain vans commonly come geared up with a variety of safety features, such as brake systems, reverse warning devices, seat belts, and emergency give up systems, to make sure the security of operators and these round them.

6. Q: How do you operate the day by day renovation of BYD warehouse attain trucks?

A: Daily upkeep is necessary for the overall performance and sturdiness of forklifts. BYD generally gives protection pointers and plans, which include duties such as everyday inspections, section replacements, cleaning, and lubrication. Operators and preservation personnel have to comply with these tips for forklift maintenance.

7. Q: Does BYD grant after-sales aid and restore services?

A: Yes, BYD commonly provides after-sales help and restore services, which includes education for upkeep personnel, spare components supply, renovation and servicing plans, and technical support. If you come upon problems or require repairs, you can contact an licensed BYD carrier core or provider for assistance.

8. Q: What optionally available attachments and configurations are on hand for BYD warehouse attain trucks?

A: BYD commonly presents a range of non-compulsory attachments and configurations to meet special software needs. These attachments and configurations may additionally consist of one-of-a-kind kinds of forks, attachments, cabin configurations, hydraulic functions, and different customization alternatives to adapt to unique work environments and tasks