BYD Electric Powered Pallet Jack

Safety

• Electric braking computer • Programmable Speed controlling • Power-off protection • Emergency swap • Multi-functional take care of • Turning speed limit

Performance

• Iron-phosphate battery • AC strength device • DC lifting gadget • Small turning radius • Rapid charging & opportunity charging • Power nap • Flexible software program opportunities

Digital (LCD) multifunction display

– Alarm slight – Maintenance indicator – Low tempo indicator – Error code – Self-diagnostics – Built-in analyzer

Operability & Ergonomics

• Automatic parking brake • Easy connection charging port

Serviceablity

• AC strain motor (no brushes or commutator) • DC lifting motor • Analyzing connection at charging port • Maintenance-free battery case • Easy-access controllers • Easy-lift battery hood

Product Description:

The BYD Electric Walkie Pallet Jack makes pulling product thru the warehouse environment friendly and convenient. Ideal for mid-distance runs as properly as loading and unloading trailers, this electric powered pallet jack is a handy, multi-use answer for almost any application.

Product Parameter:

Identification | 1.1 | Manufacturer | BYD | ||

1.2 | Model | P30A | |||

1.3 | Drive | Electric | |||

1.4 | Operator type | Stand-on/Pedestrian | |||

1.5 | Load capacity | Q | kg | 3000 | |

1.6 | Load center | C | mm | 600 | |

weight | 2.1 | Service weight including battery | kg | 700 | |

Wheels | 3.1 | Wheel type | PU | ||

Dimensions | 4.4 | Lift height | h3 | mm | 120 |

4.19 | Overall Length (with/without the pedal raised) | l1 | mm | 1960 | |

4.20 | Body Length (excluding forks) | l2 | mm | 760 | |

4.21 | Overall width | b1 | mm | 790 | |

4.22 | Fork dimensions | s/e/l | mm | 60×170×1200 | |

4.25 | Width over fork | b2 | mm | 685 | |

4.35 | Turning radius | Wa | mm | 1800 | |

Performance Data | 5.1 | Travel speed, with/without load | Km/h | 6/6 | |

5.2 | Lift speed, with/without load | mm/s | 13/27 | ||

5.3 | Lowering speed, with/without load | mm/s | 40/30 | ||

5.8 | Max. gradeability, with/without load | % | 5/7 | ||

5.10 | Service brake | Electromagnetic | |||

Electric Motor | 6.1 | Drive motor type | AC | ||

6.2 | Lift motor type | DC | |||

8.4 | Sound level at the driver’s ear | dB(A) | <70 |

Classification:

Electric power steering to enable large maneuverability for the operator and limit fatigue.

Shock-absorbent, non-slip platform presents operators a tightly closed and cozy position.

Pallet jack offers operators an ergonomic and adaptable design.

Automatic shutdown when deal with is launched or placed in a vertical / horizontal position.

Optimal place of the emergency end button to make it safer.

Optional configuration:

Customized Forklift

100A Standard Charger

30A Onboard Charger

Use:

Warehousing and Logistics industry, manufacturing industry, retail industry, electronics industry, food and beverage industry, pharmaceutical industry, agriculture

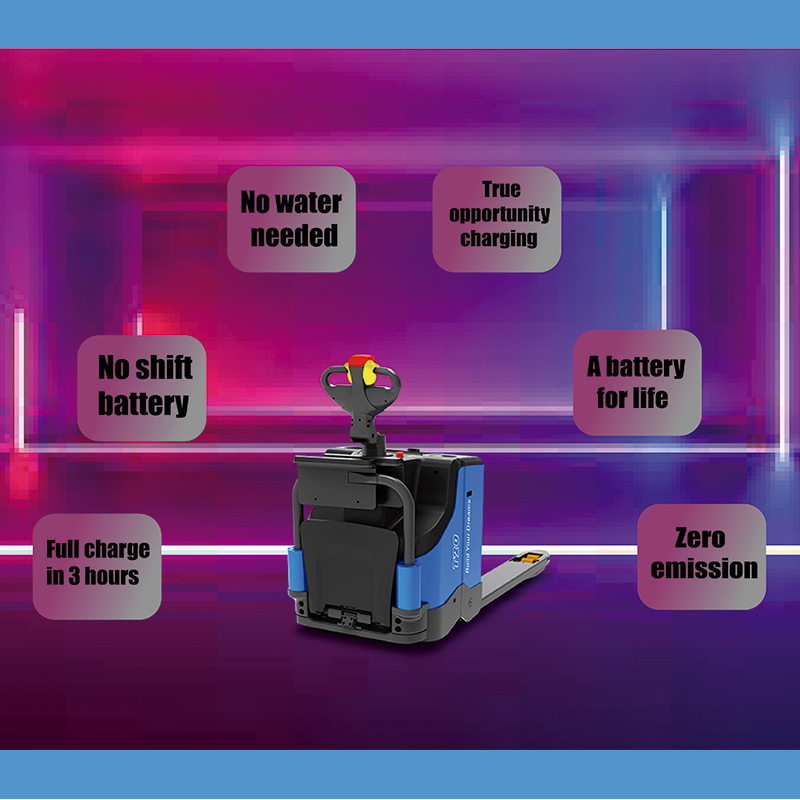

Product advantages:

Streamlined Structure: Featuring a standing-drive operation and an open-frame structure, its handy and comfy design affords a clean and except issue understandable appearance. It affords nimble and reachable operation, making it agile and efficient.

Flexible Operation: With a multi-functional control that offers limitless adjustment, it ensures a greater cozy and impenetrable operation. The electric power training desktop makes using frequent for the operator.

Human-Centric Design: Equipped with a multi-functional storage container and a versatile exhibit instrument panel, it absolutely caters to customers' wishes for storing personal requirements and viewing dashboard information clearly. It showcases a entire human-centric format for forklifts, enhancing operational comfort.

High Safety Performance: Equipped with safety guardrails and shock-absorbing foot mats, it efficaciously protects the driver. The cope with is designed with cushioning at its give up to effectively give up collisions.

Product inspection:

BYD forklift producer many times conducts rigorous product inspections and excellent manipulate when producing forklift merchandise to make certain that their nice and usual overall performance meet immoderate standards. These product inspects starts as from Raw Material Inspection: During the manufacturing process, BYD inspects the raw resources used. This consists of checking steel, digital components, lubricants, coatings, and more. Raw substances ought to meet special first-rate necessities and specifications.

Manufacturing Process Inspection: During the forklift's manufacturing process, BYD video show devices and inspects key technique steps to make positive that each and every element meets layout specifications. This consists of inspections of welding, mechanical processing, electrical connections, and extraordinary aspects.

Performance Testing: After the forklift is assembled, typical overall performance checking out is conducted. This consists of checking engine power, suspension systems, brake systems, driver manipulate systems, and more to make certain that the forklift's common overall performance meets distinctive standards.

Safety Testing: BYD forklifts undergo safety checking out to make certain compliance with relevant safety standards. This consists of collision tests, steadiness tests, electrical protection tests, and others.

Quality Control: BYD implements a magnificent manipulate system, consisting of inspection and checking out procedures, file records, employee training, and more, tomake positive product consistency and quality.

Final Inspection: After the completion of forklift production, a final inspection is performed. This consists of a whole take a seem at of the whole forklift to make certain that all components are hooked up correctly, there are no obvious defects, and average overall performance is excellent.

Product Certification: Once the forklifts pass over all crucial inspections and tests, they can also moreover get maintain of relevant product certifications to exhibit compliance with international and regional quality and safety standards.

Packaging and transportation:

The packaging and transportation of forklifts are commonly dealt with through capability of the producer and suppliers to make positive that the merchandise are now now not damaged all thru transit.

Packaging: Forklifts are usually packaged beforehand than leaving the manufacturing facility to defend their seem to be and mechanical elements from damage. Packaging typically consists of the use of wooden crates, foam padding, plastic film, and strapping materials to make sure that the forklifts are now now not affected through ability of bumps and collisions all via transportation.

Inspection and Testing: Before leaving the factory, producers regularly conduct rigorous inspections and attempting out on the forklifts to make positive that they attribute excellent and can be safely transported. This consists of checking mechanical components, batteries, brake systems, and more.

Shipping: Once the forklifts are suitable packaged and miss inspection, they are prepared for shipping. Forklifts can be transported to their vicinity with the resource of avenue transportation, sea shipping, air freight, or one of a kind methods, relying on the distance, neighborhood or Destination on client requirements.

Documentation and Permits: Depending on the requirements of the locationor region, relevant archives and approves may additionally moreover desire to be provided to make positive that the forklifts can legally enter and be used in the place or area

Company introduction:

BYD Forklift, hooked up in 2009, is a subsidiary of BYD Co., Ltd., located in the Zhenjiang district of Shaoguan City. The whole funding for the undertaking is 515 million RMB, protecting an neighborhood of about 700,000 rectangular meters. It is broadly speaking responsible for producing BYD electric powered forklift series, which consists of the electric powered counterbalance forklift series, electric powered warehouse forklift series, and electric powered tow tractor series, amongst others.

BYD Forklift possesses a entire forklift manufacturing line, which consist of four machining and welding lines, one painting line, and three ultimate assembly lines, achieving an annual manufacturing capability of 30,000 units. Furthermore, the manufacturing facility has a specialist checking out line and a entire satisfactory system, licensed below ISO9001, to make certain the superb of every forklift and grant purchasers with first-rate great and superb service.

BYD Forklift has normally aimed to create a primary world agency in electric powered forklifts. 'Pursuing excellence and non-stop innovation' is the enchancment philosophy of BYD Forklift, constantly optimizing and upgrading its products, defending a excellent fluctuate of functions from warehousing and logistics to port and terminal logistics. The market growth consists of a couple of industries such as pharmaceuticals, food, cold chain processing, cosmetics, logistics, and more. In the gadget of market feedback, BYD electric powered forklifts have definitely established their giant advantages in inexperienced environmental security and power efficiency, receiving unanimous reward from customers at home and abroad, laying a secure foundation for BYD electric powered forklifts to flip out to be a globally depended on brand.

In response to market enchancment needs, BYD Forklift is creating a entire electric powered forklift base in the Ningbo Industrial Park, integrating look up and development, production, sales, and after-sales service. After completion, the challenge will be based totally in the Yangtze River Delta, masking East China and radiating nationwide and for export. The deliberate entire funding for BYD Forklift's Ningbo manufacturing facility is 5 hundred million RMB, which will consist of a 60,000 rectangular meters facility encompassing methods such as automobile machining, welding, painting, assembly, and modification, with the potential to produce 20,000 electric powered counterbalance forklifts and 30,000 warehouse forklifts annually.

Customer visit:

Before conducting patron visits, the profits or client provider businesses usually time desk appointments with consumers and design the visit's timing, location, and agenda. This is performed by using smartphone calls, emails, or one-of-a-kind verbal trade methods. The earnings or patron service companies do specify the topics to be referred to with the customers, which consist of product presentations, situation resolution, training, business agency negotiations, or contract signings, amongst others. BYD’s client company companies regularly put collectively relevant archives and presentation supplies to share with purchasers which might also additionally embody product manuals, presentation slides, samples, and more.

After the go to concludes, BYD’s profits or customer provider businesses generally file the meeting's content, speak outcomes, and plans for the subsequent steps. We moreover preserve ongoing dialog with consumers to make positive their needs are met

FAQ:

1. Q: What industries are BYD pallet dealing with forklifts excellent for?

A: BYD pallet dealing with forklifts are normally fantastic for a quantity industries, such as warehousing and logistics, manufacturing, retail, electronics, foods and beverage, pharmaceuticals, and more. They are used for transporting and stacking goods, bettering logistics efficiency.

2. Q: What are the special fashions and capacities of BYD pallet dealing with forklifts?

A: BYD offers a differ of fashions and capacities for pallet managing forklifts to meet the specific needs of terrific customers. The want of model and manageable depends upon on your specific software program requirements and working environment.

3. Q: What electricity furnish do these forklifts use?

A: BYD pallet coping with forklifts typically use batteries as their electrical energy source. This is finished to limit emissions, beautify energy efficiency, and reduce noise.

4. Q: Is working BYD pallet managing forklifts available to learn?

A: Operating BYD pallet managing forklifts is commonly fairly convenient to learn, alternatively operators prefer to suffer teaching and collect the relevant driver's license. BYD generally affords training and academic elements to make positive that operators apprehend included operation and splendid practices.

5. Q: Do these forklifts have safety features?

A: Yes, BYD pallet dealing with forklifts usually come geared up with a variety of safety features, inclusive of brake systems, reverse warning devices, seat belts, and emergency braking systems, to make certain the safety of operators and these spherical them.

6. Q: How do you maintain and issuer BYD pallet dealing with forklifts?

A: Maintenance and servicing are quintessential for the average overall performance and sturdiness of forklifts. BYD commonly affords renovation and servicing pointers and plans, covering obligations such as every day inspections, segment replacements, cleaning, and lubrication. Operators and safety personnel need to comply with these tips for renovationand servicing.

7. Q: Does BYD supply after-sales aid and repair services?

A: Yes, BYD generally offers after-sales assist and restoration services, consisting of schooling for protection personnel, spare factors supply, renovation and servicing plans, and technical support. If you come throughout troubles or require repairs, you can contact an accredited BYD provider core or dealer for assistance.

8. Q: What optionally reachable attachments and configurations are on hand for these forklifts?

A: BYD typically affords a range of optionally available attachments and configurations to meet specific utility needs. These may additionally moreover consist of a variety of kinds of forks, attachments, special seat and cabin configurations, and distinct customization options.